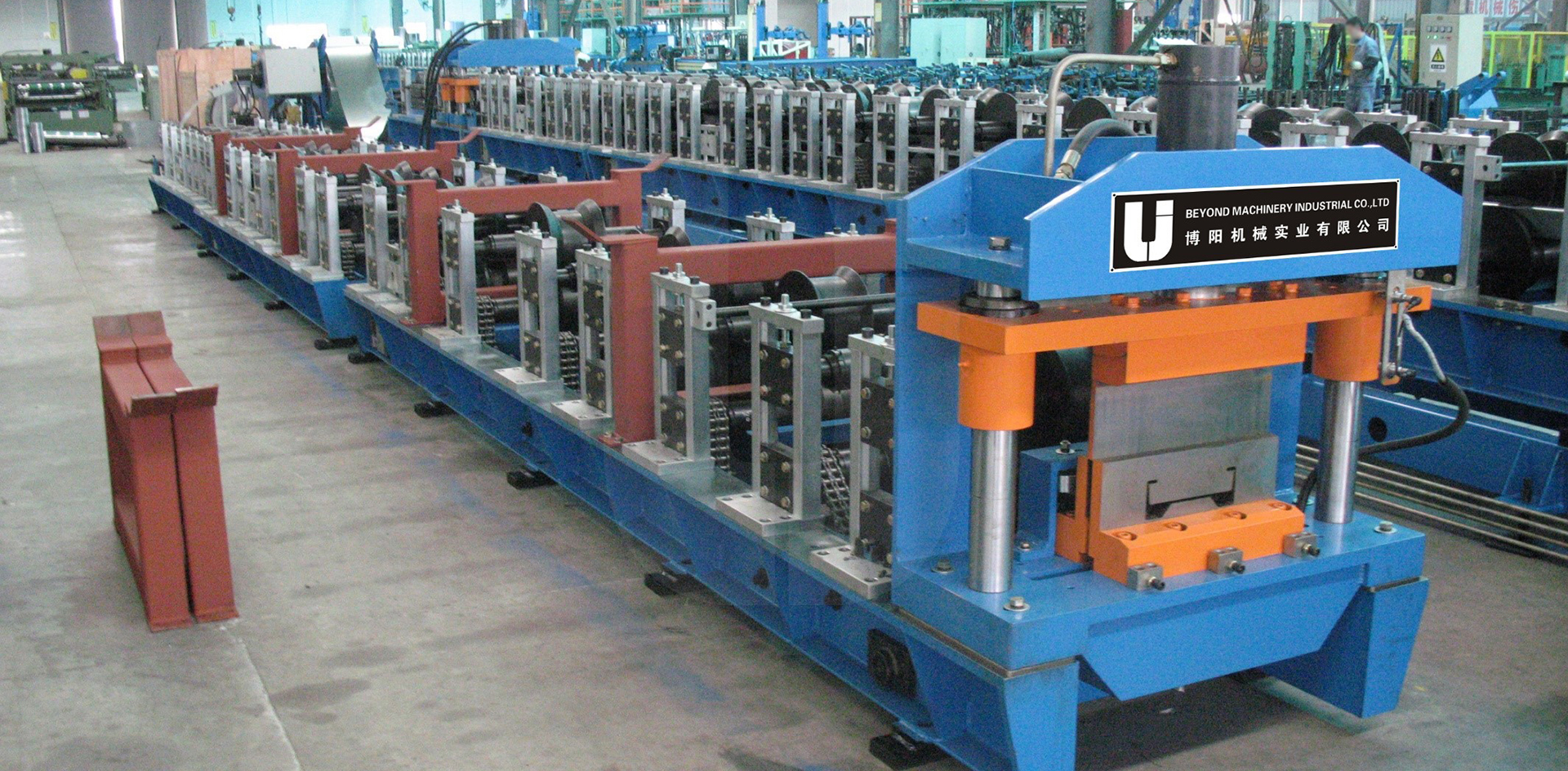

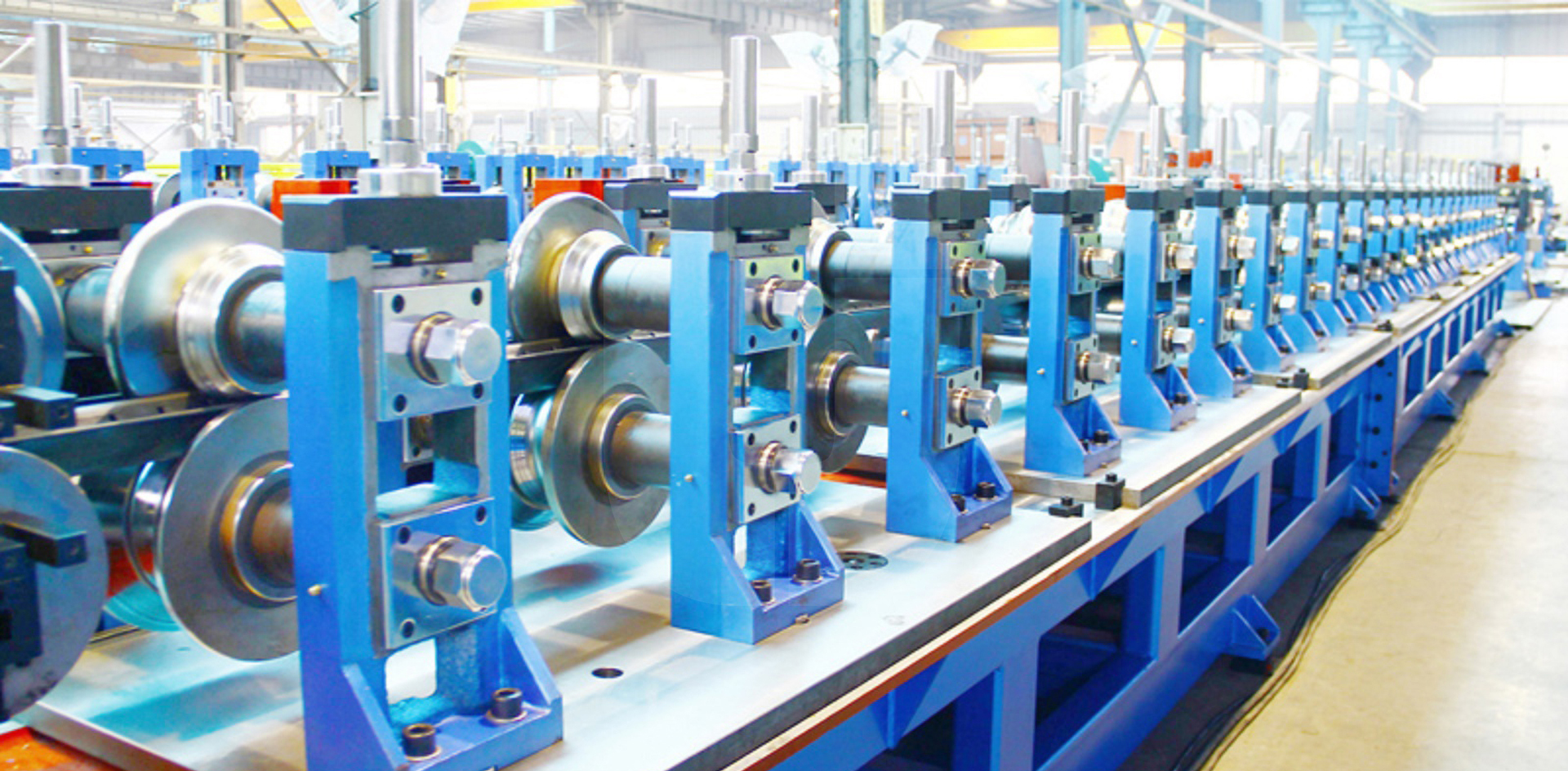

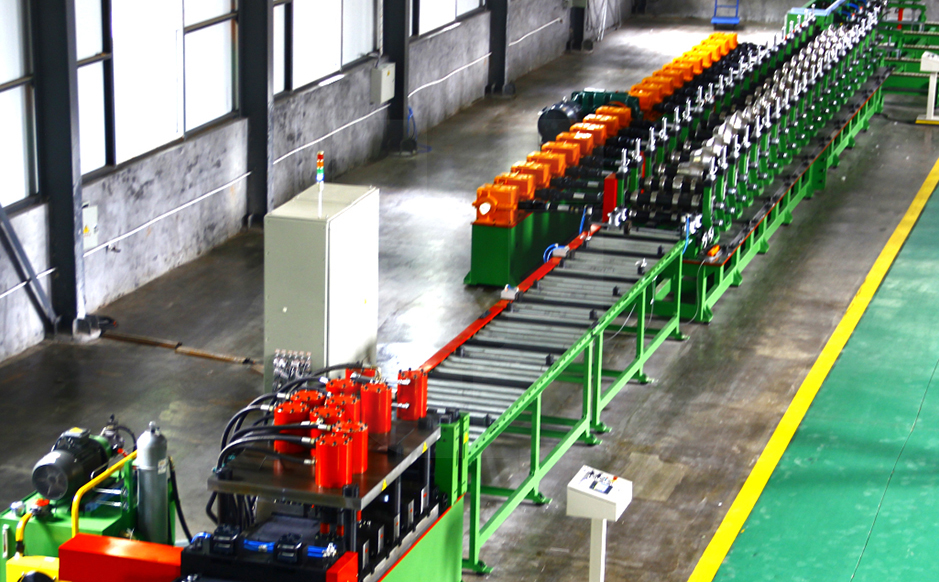

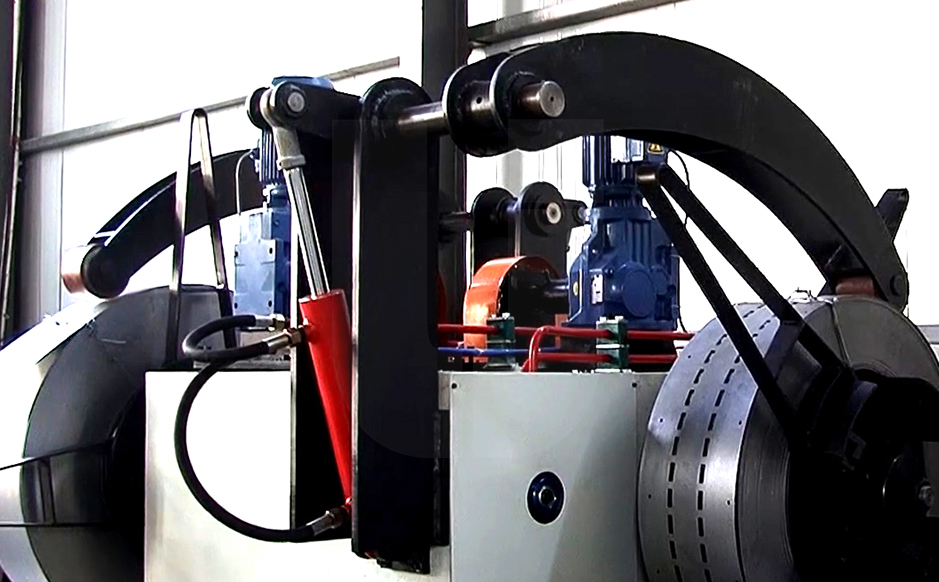

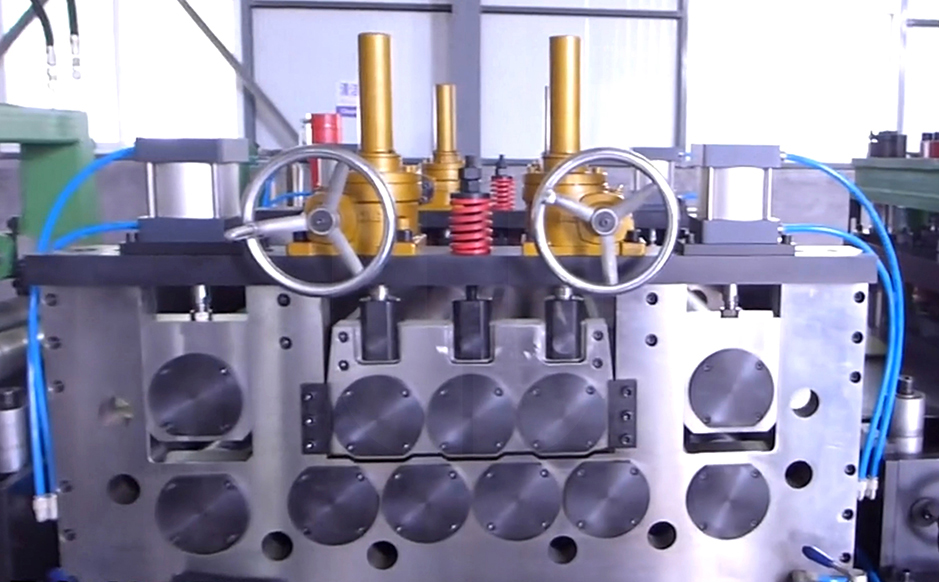

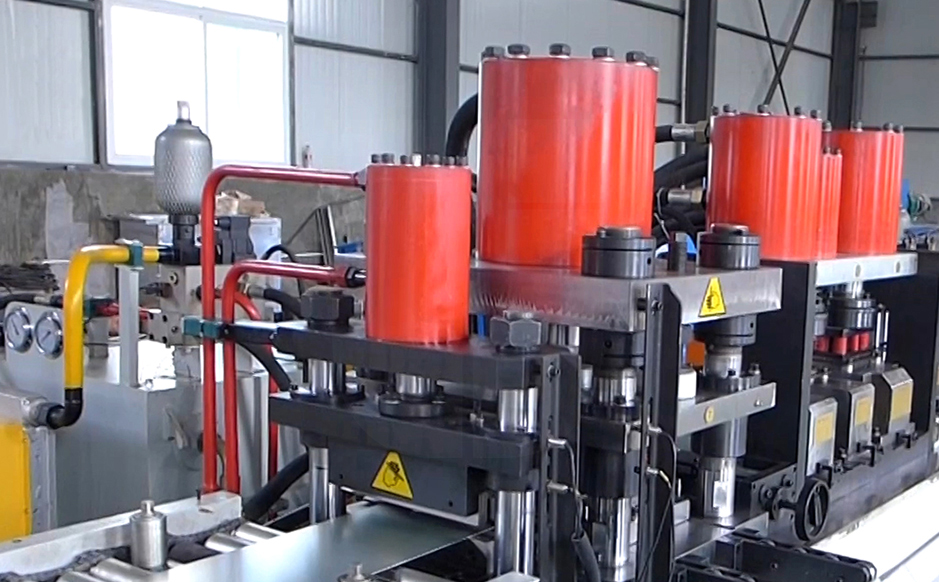

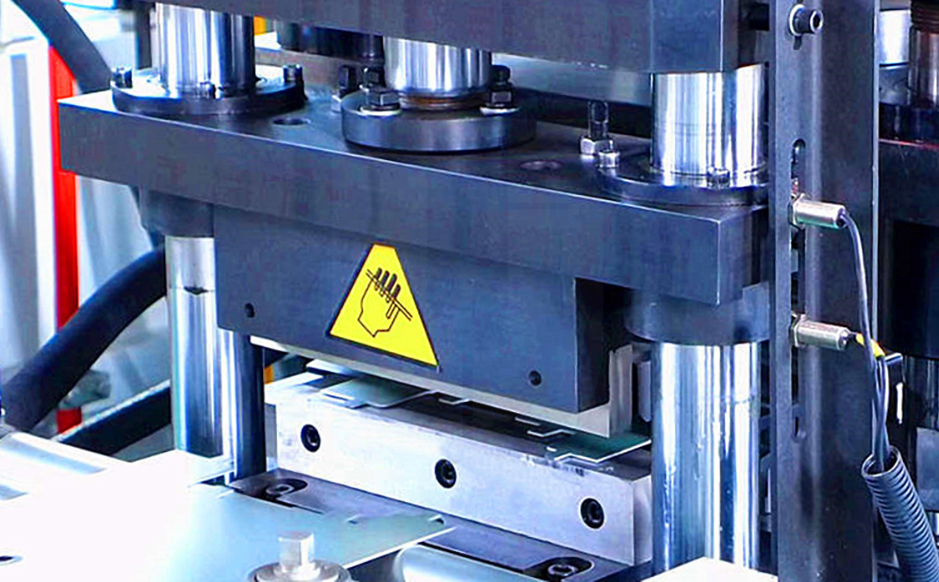

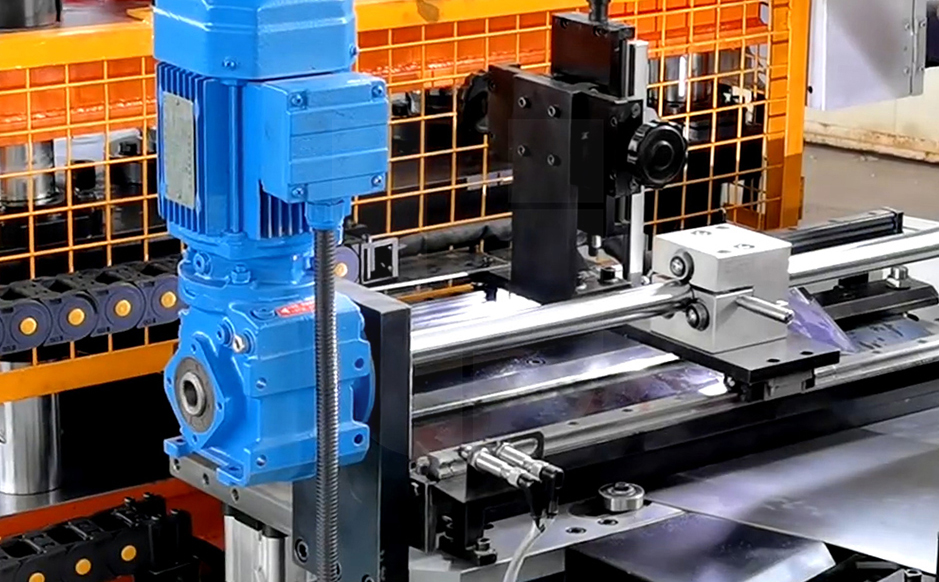

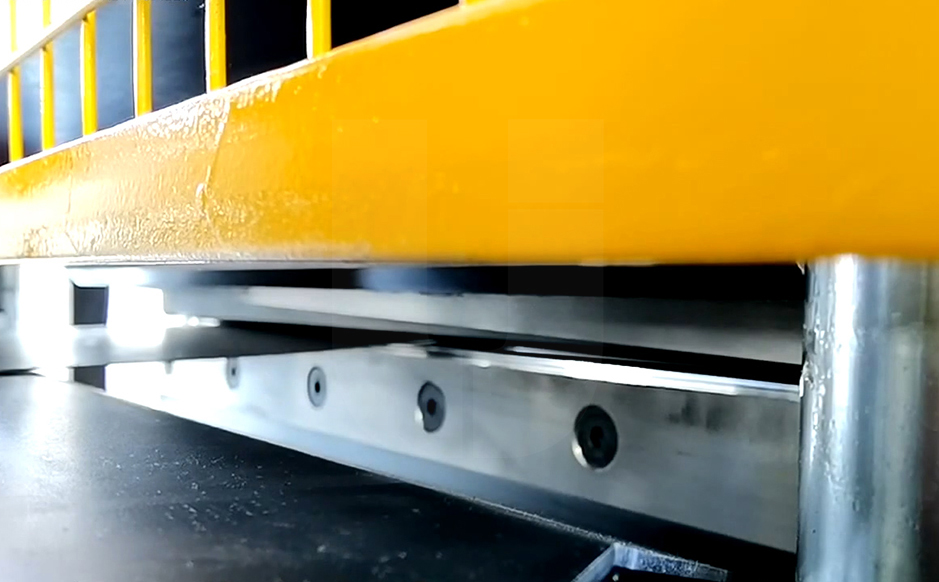

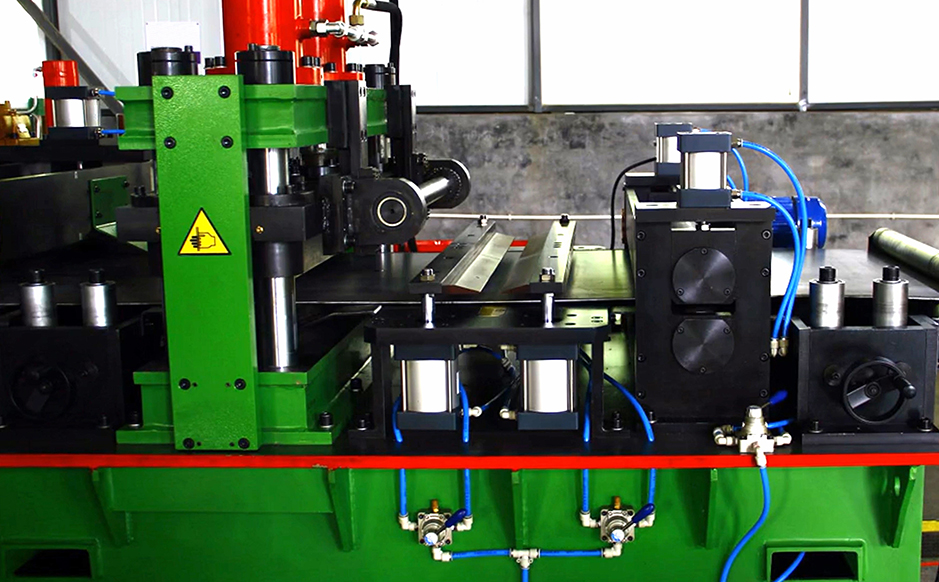

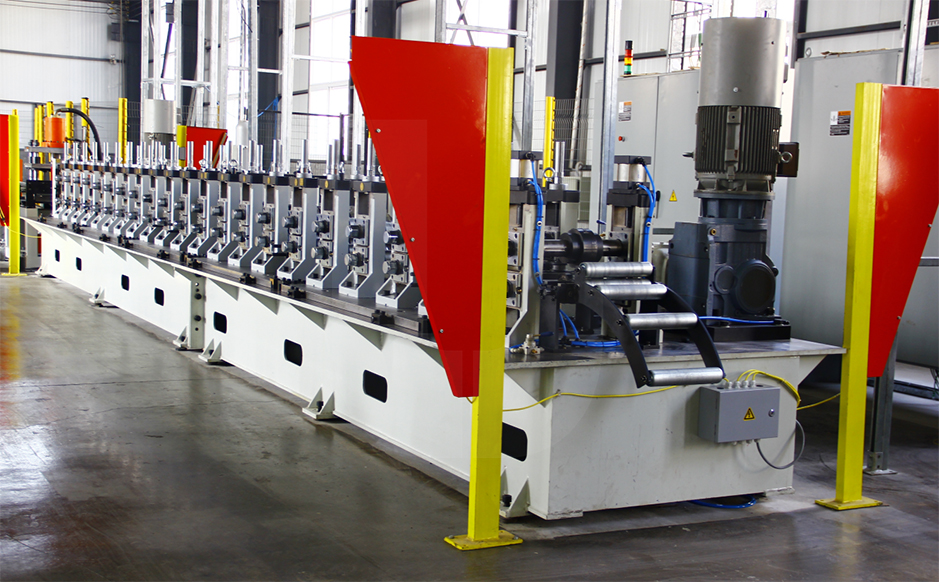

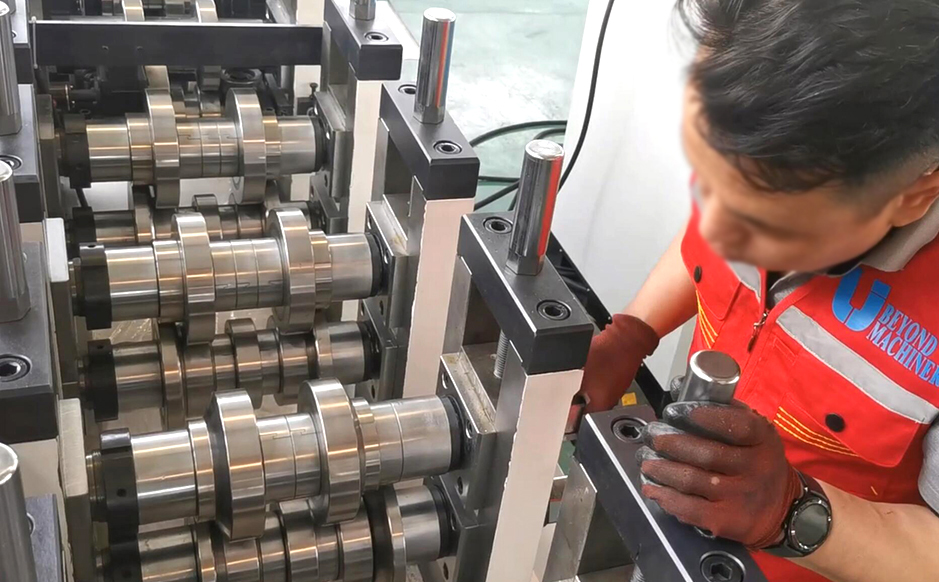

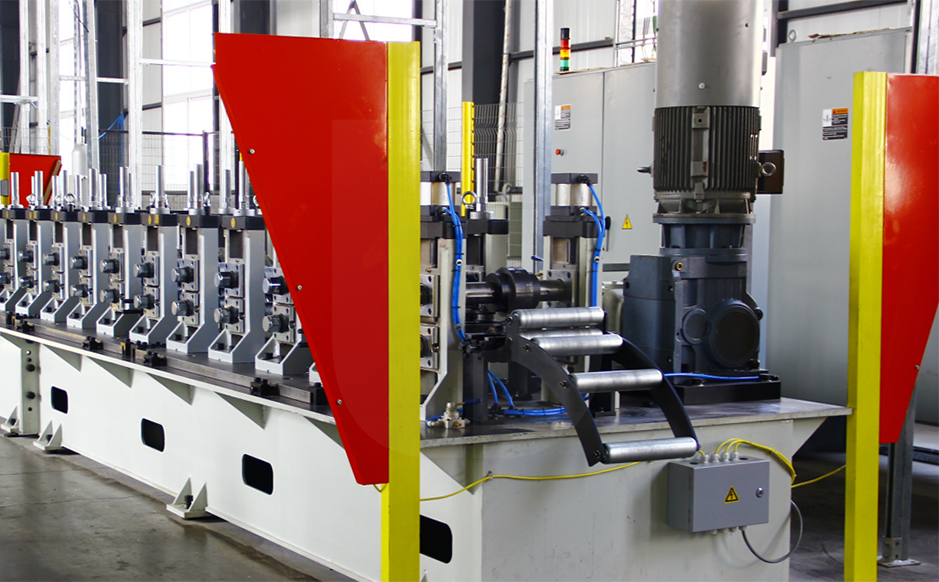

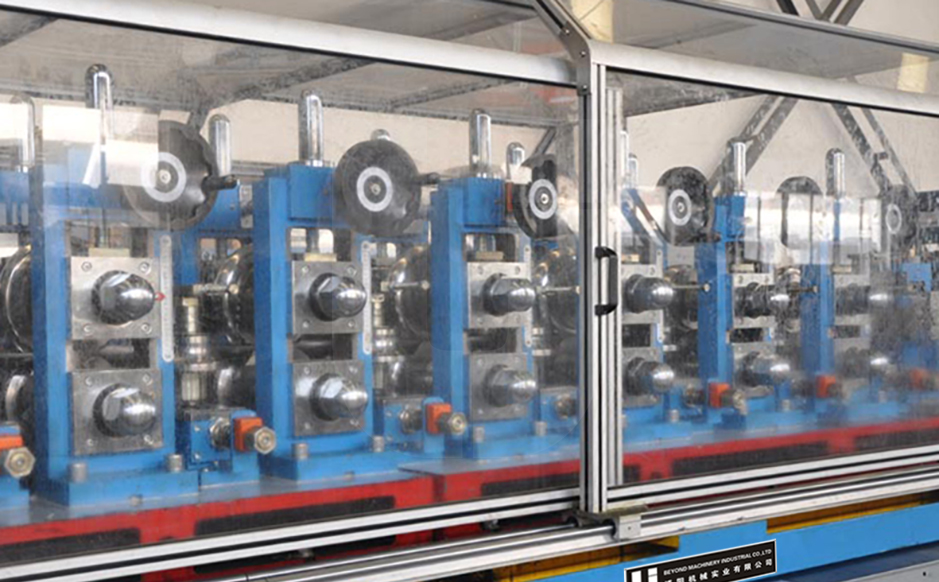

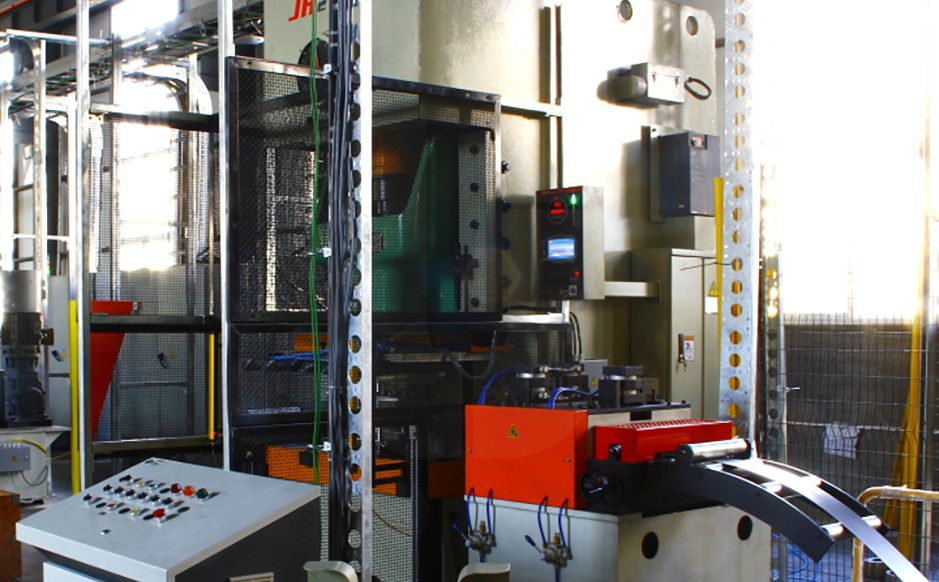

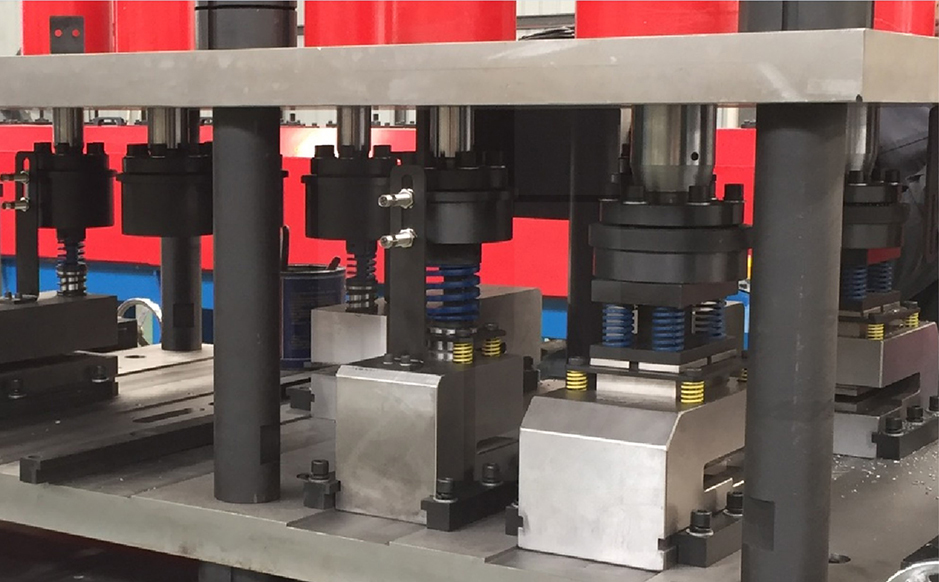

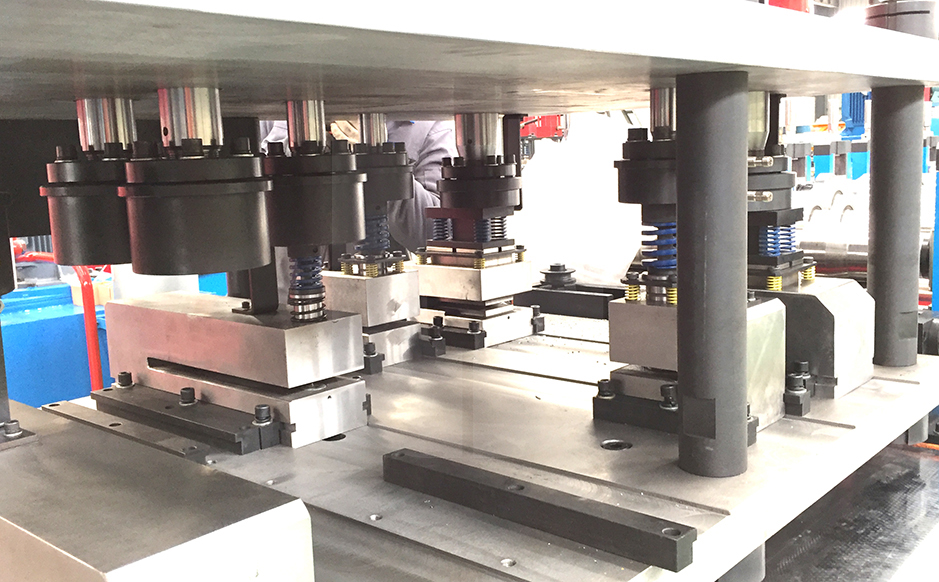

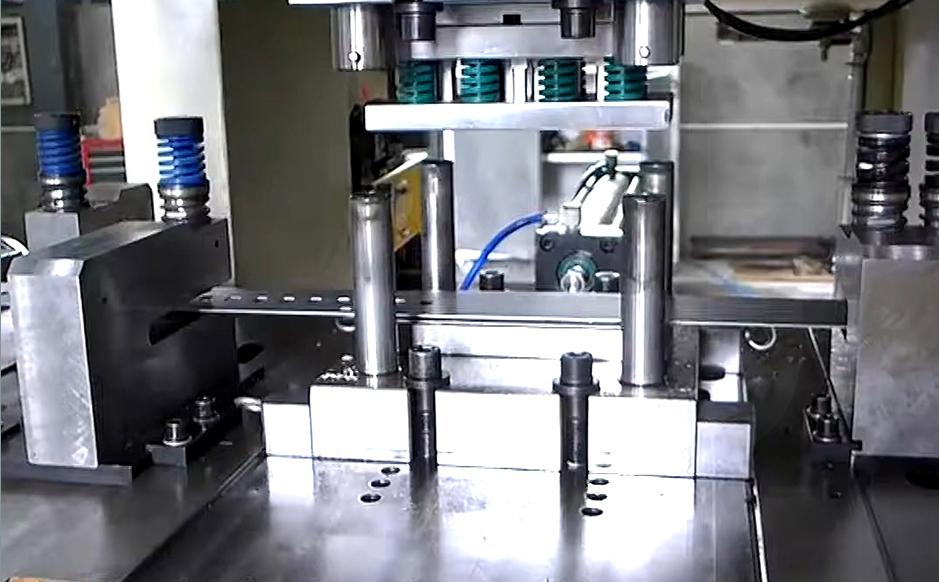

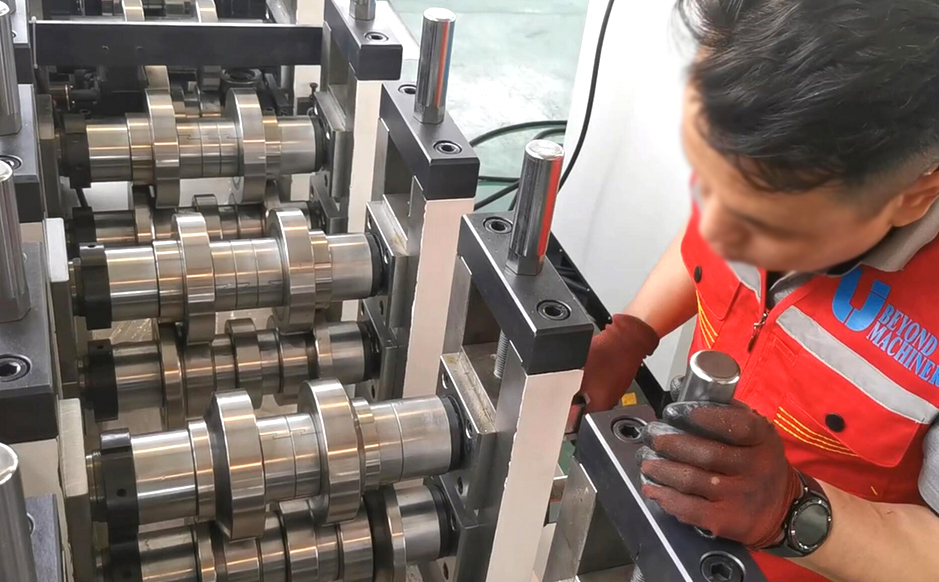

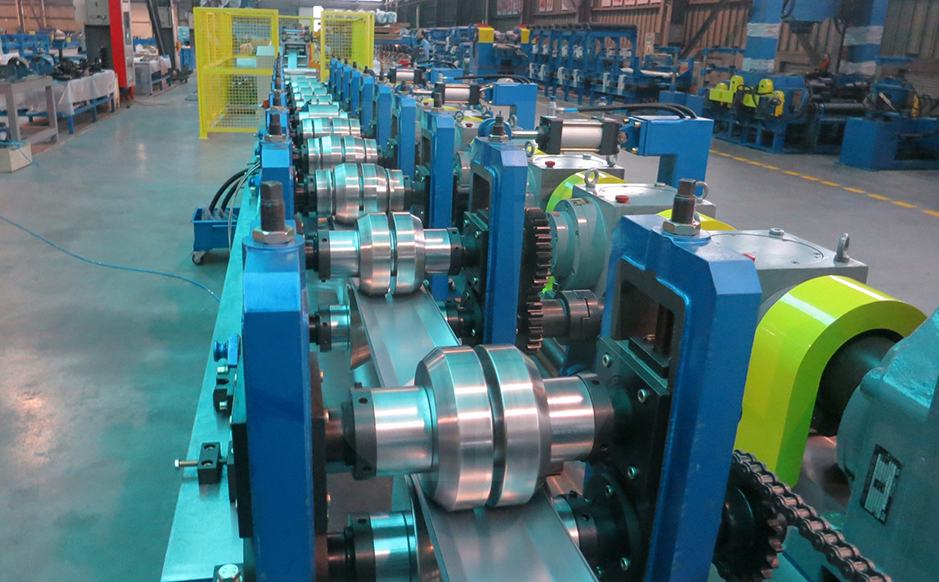

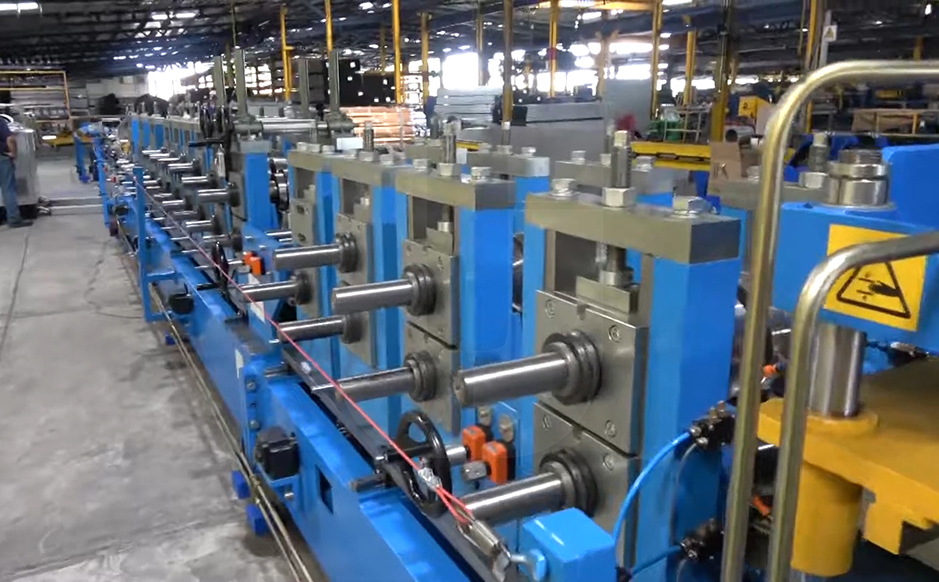

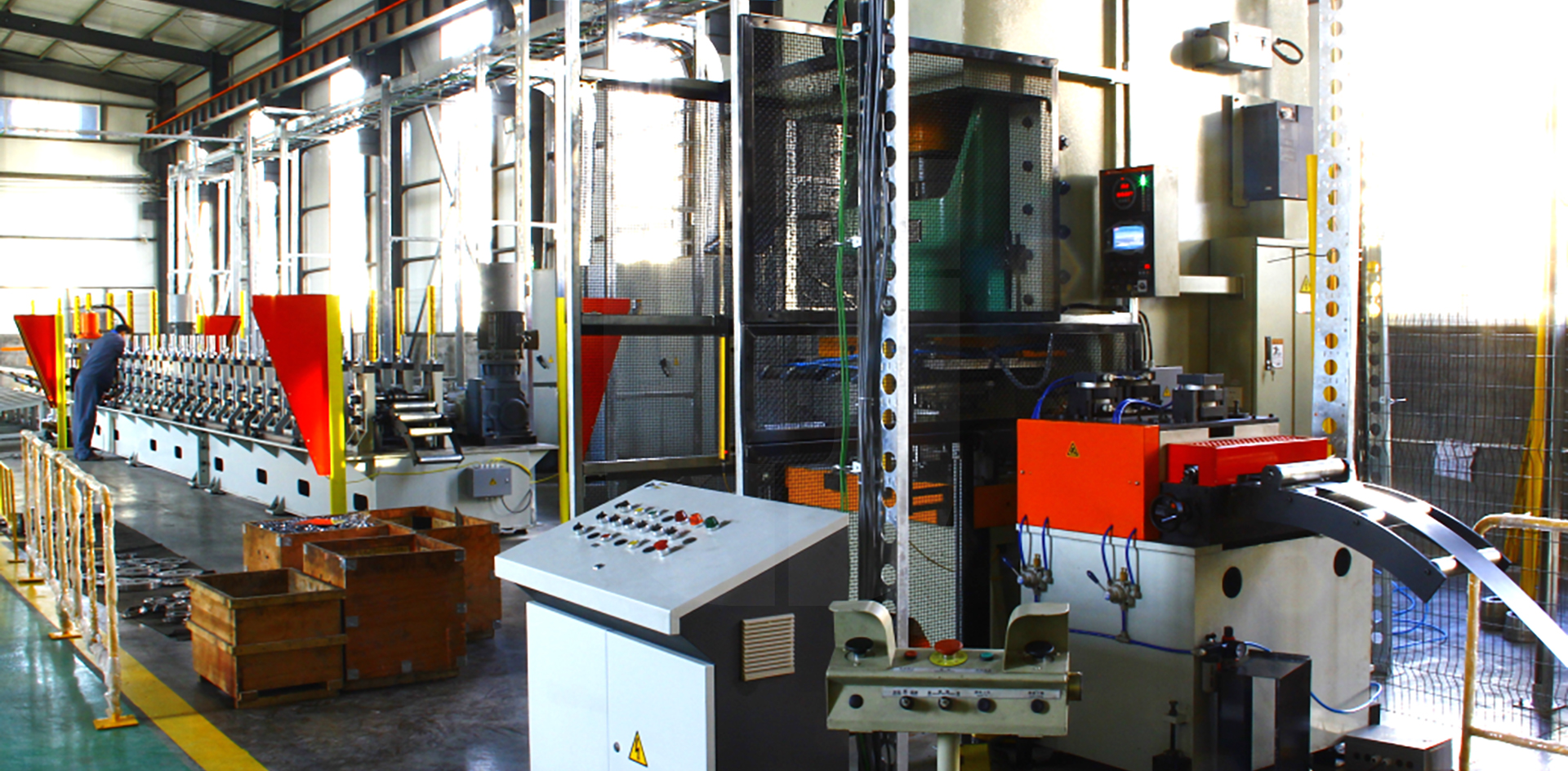

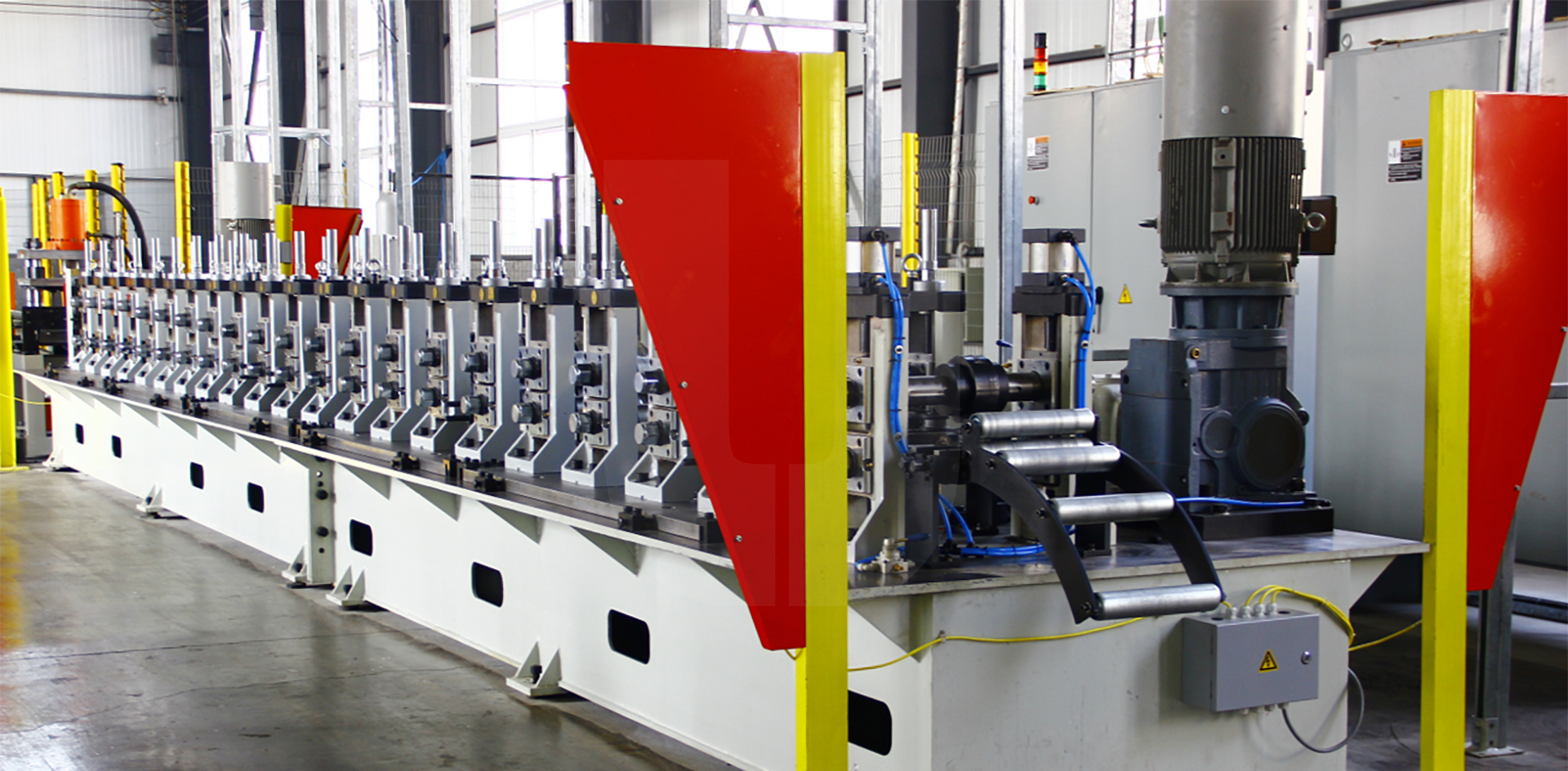

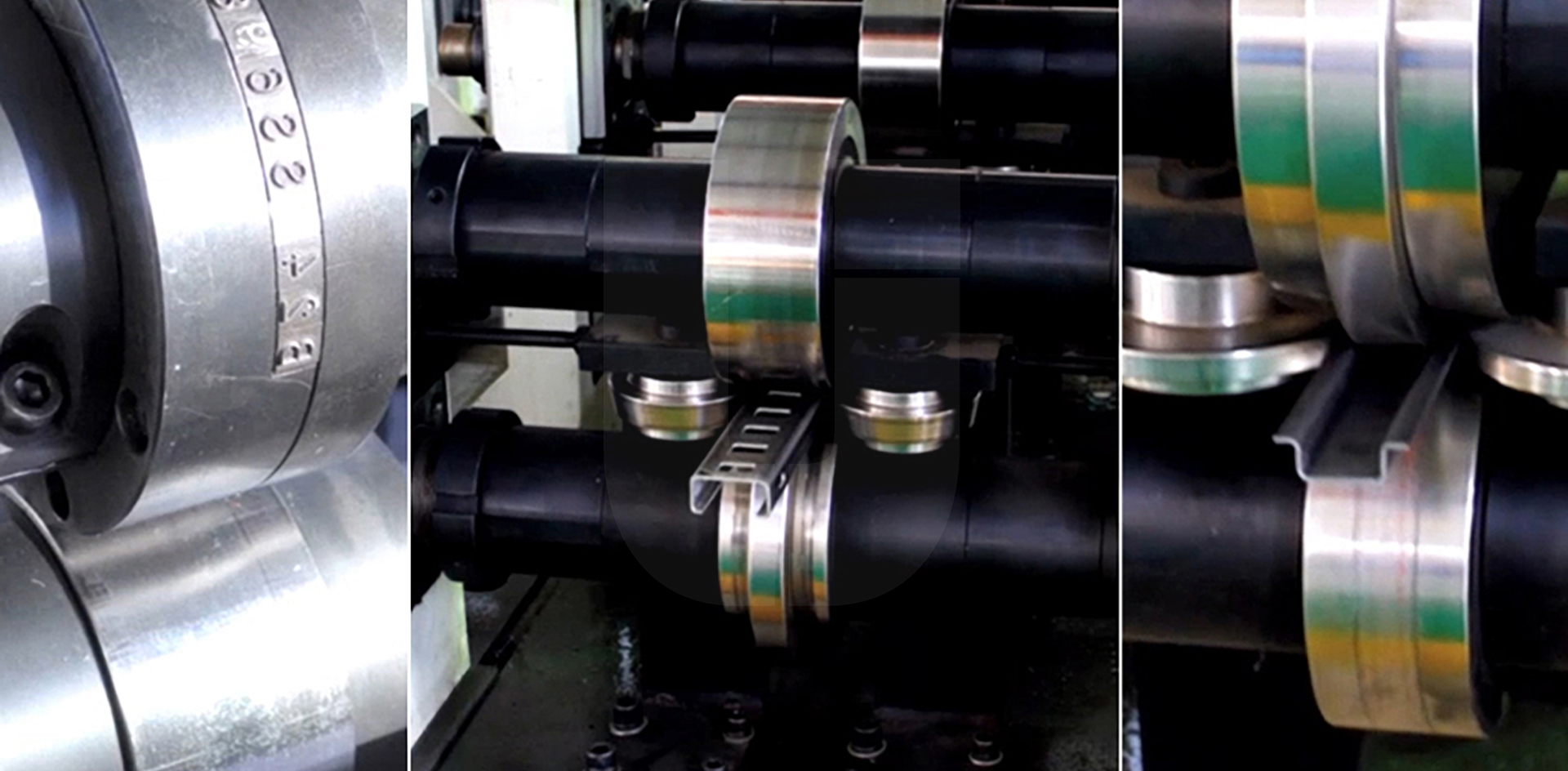

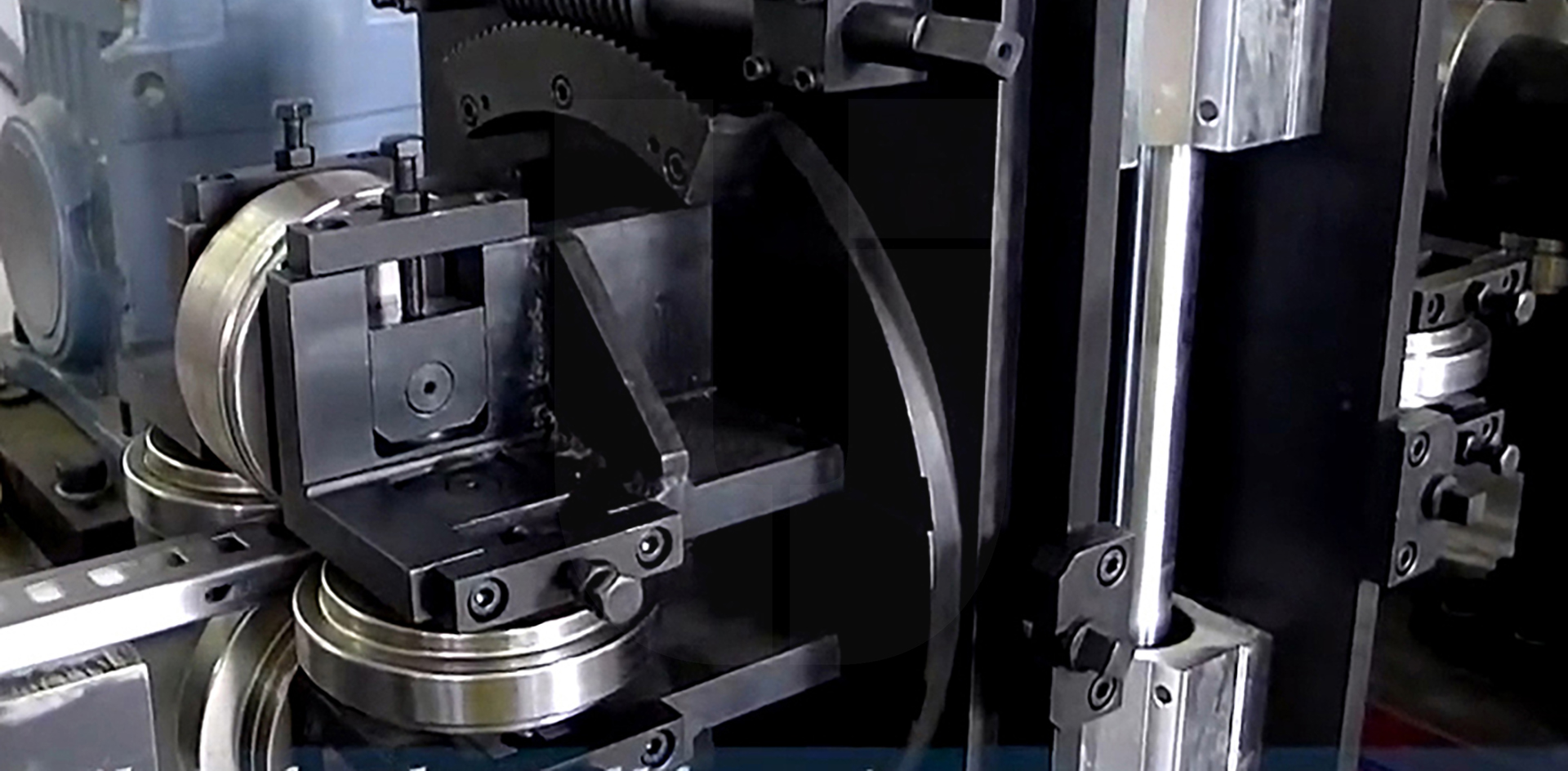

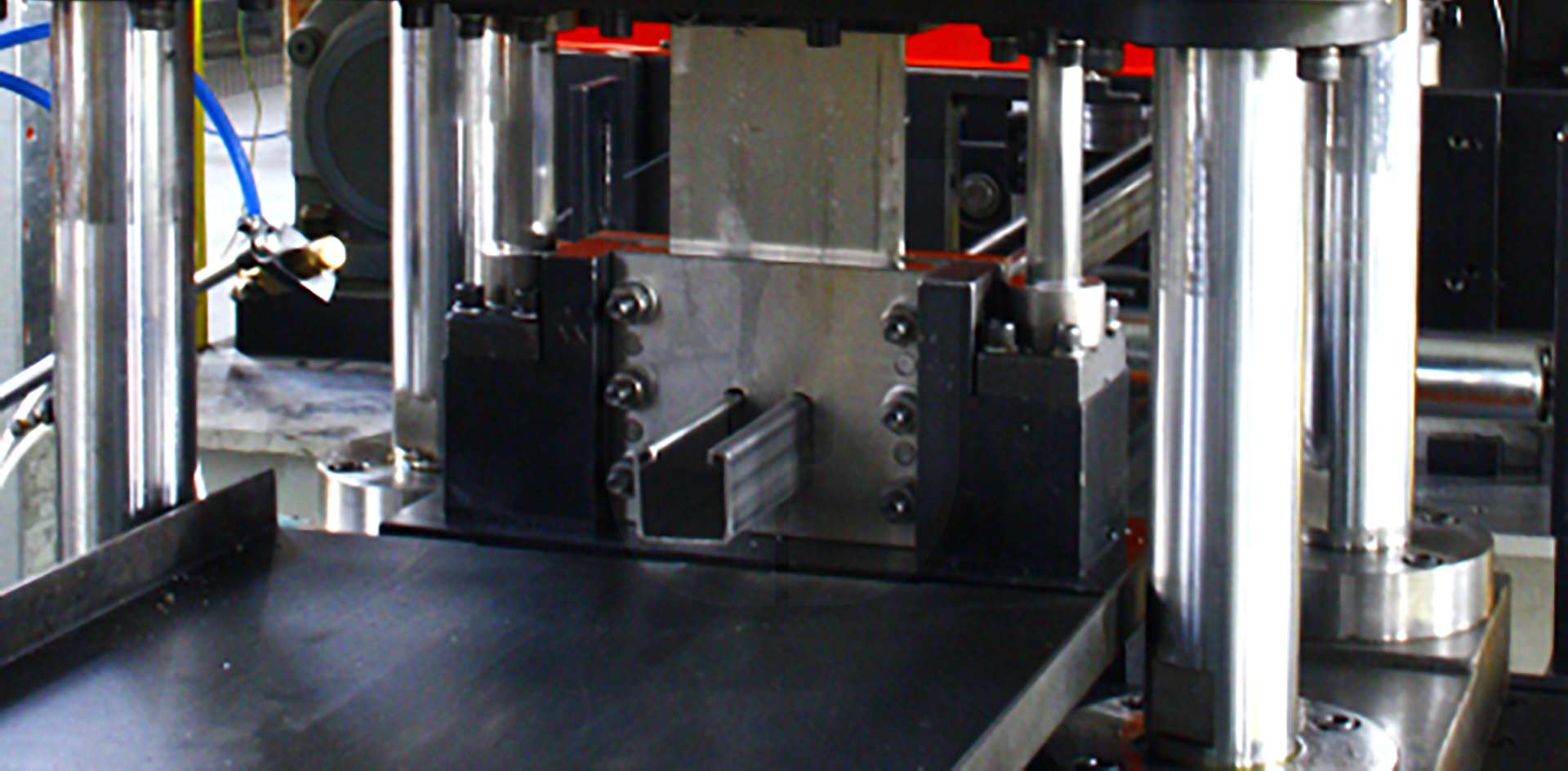

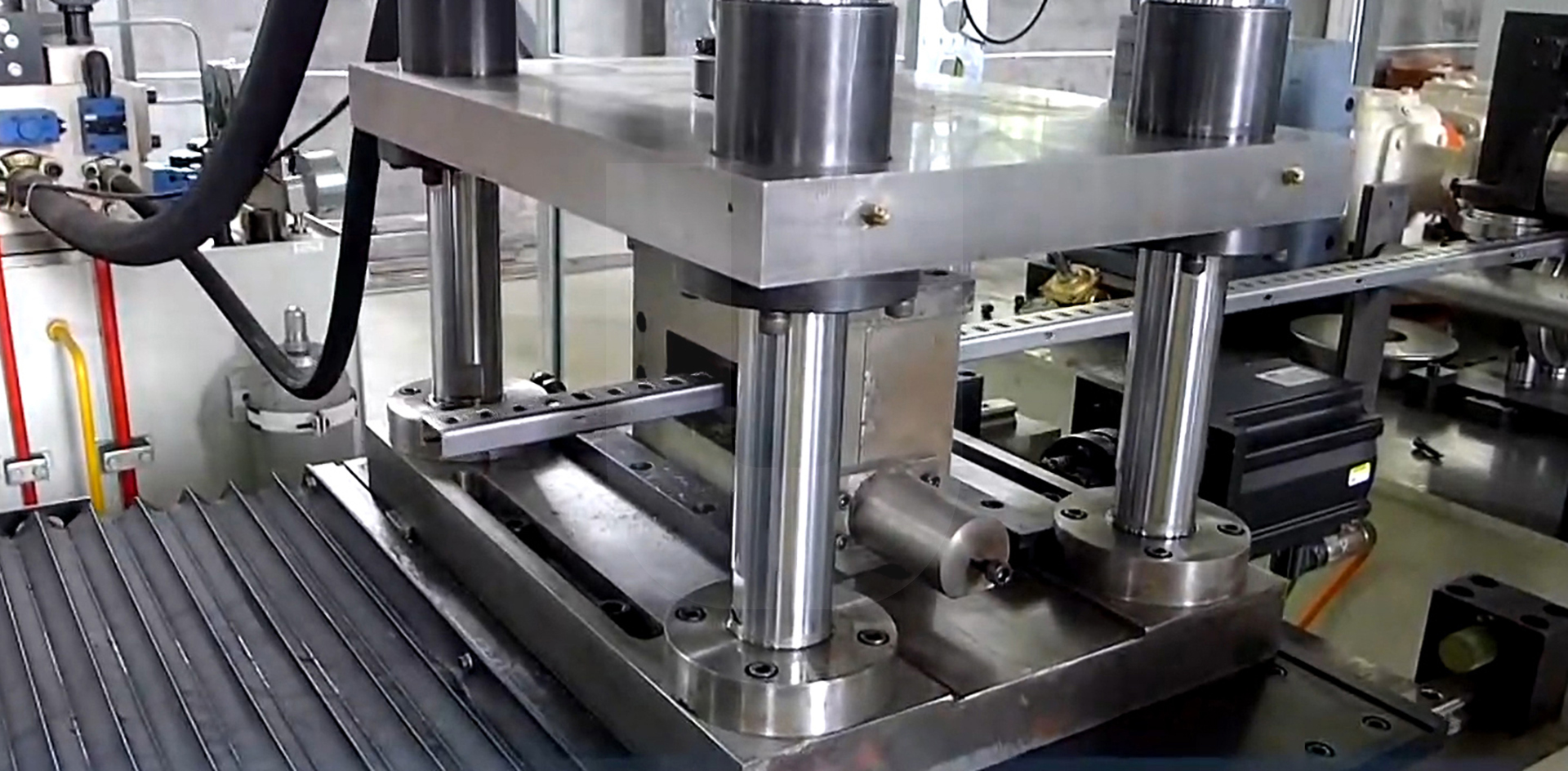

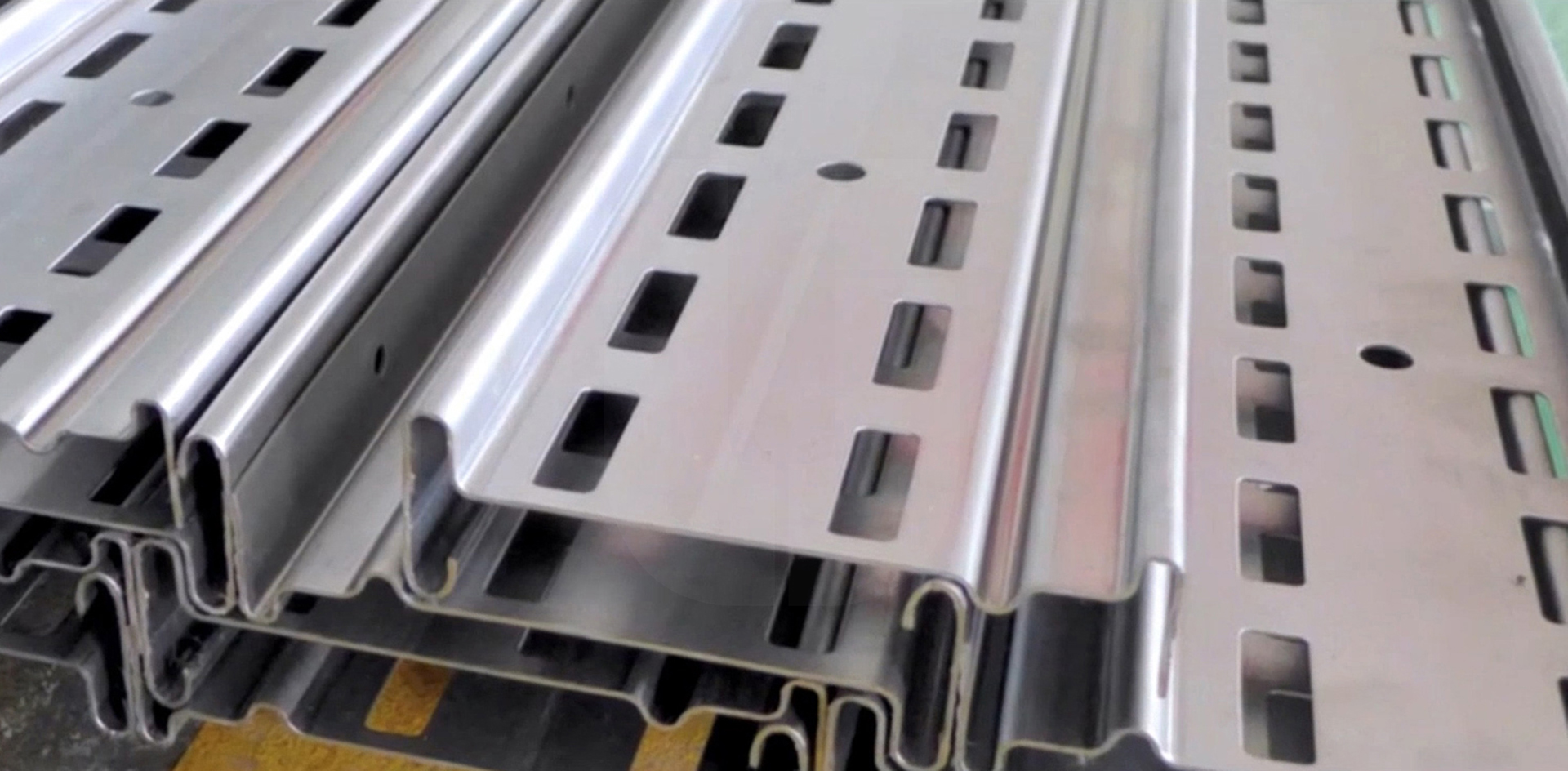

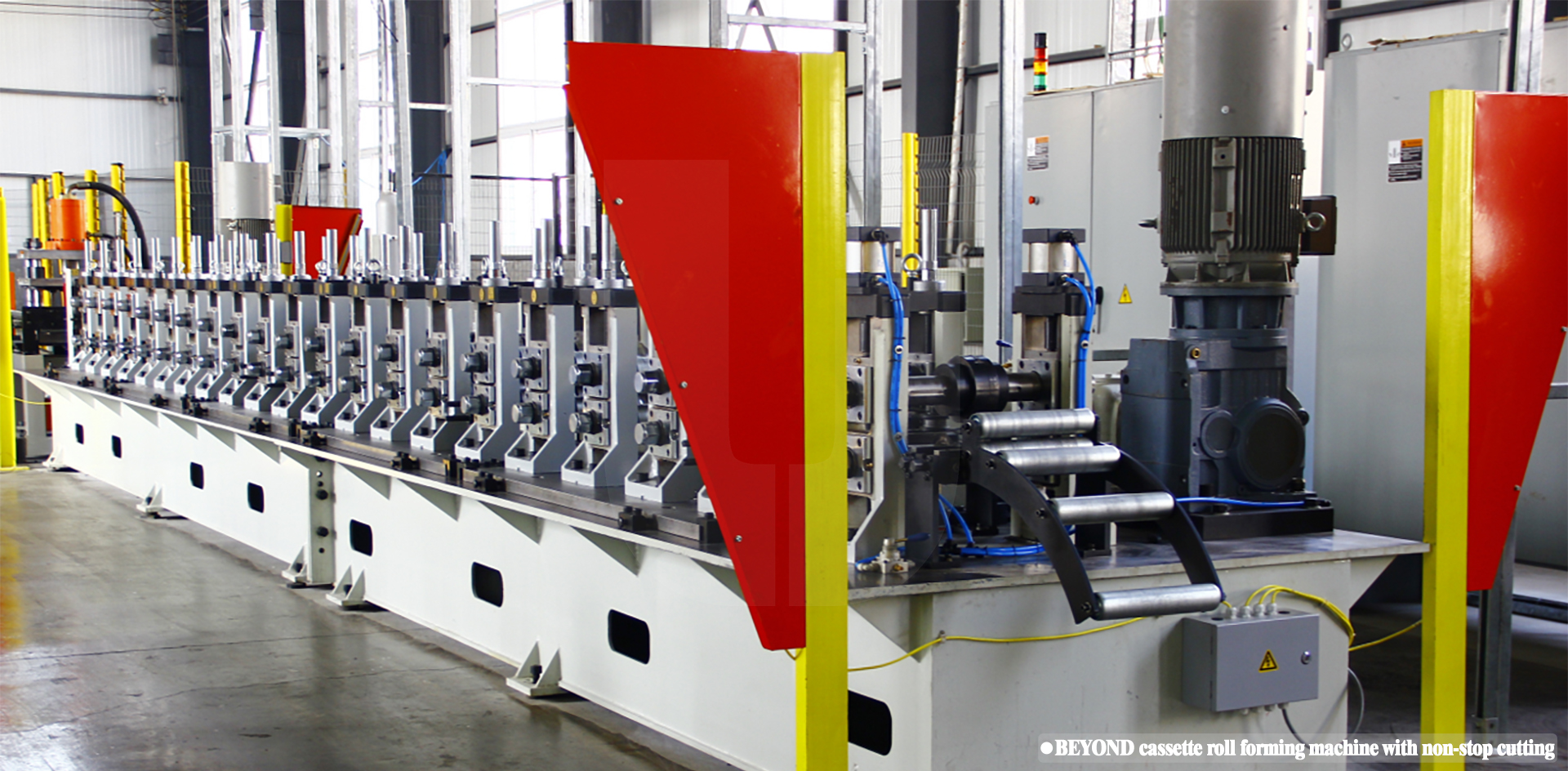

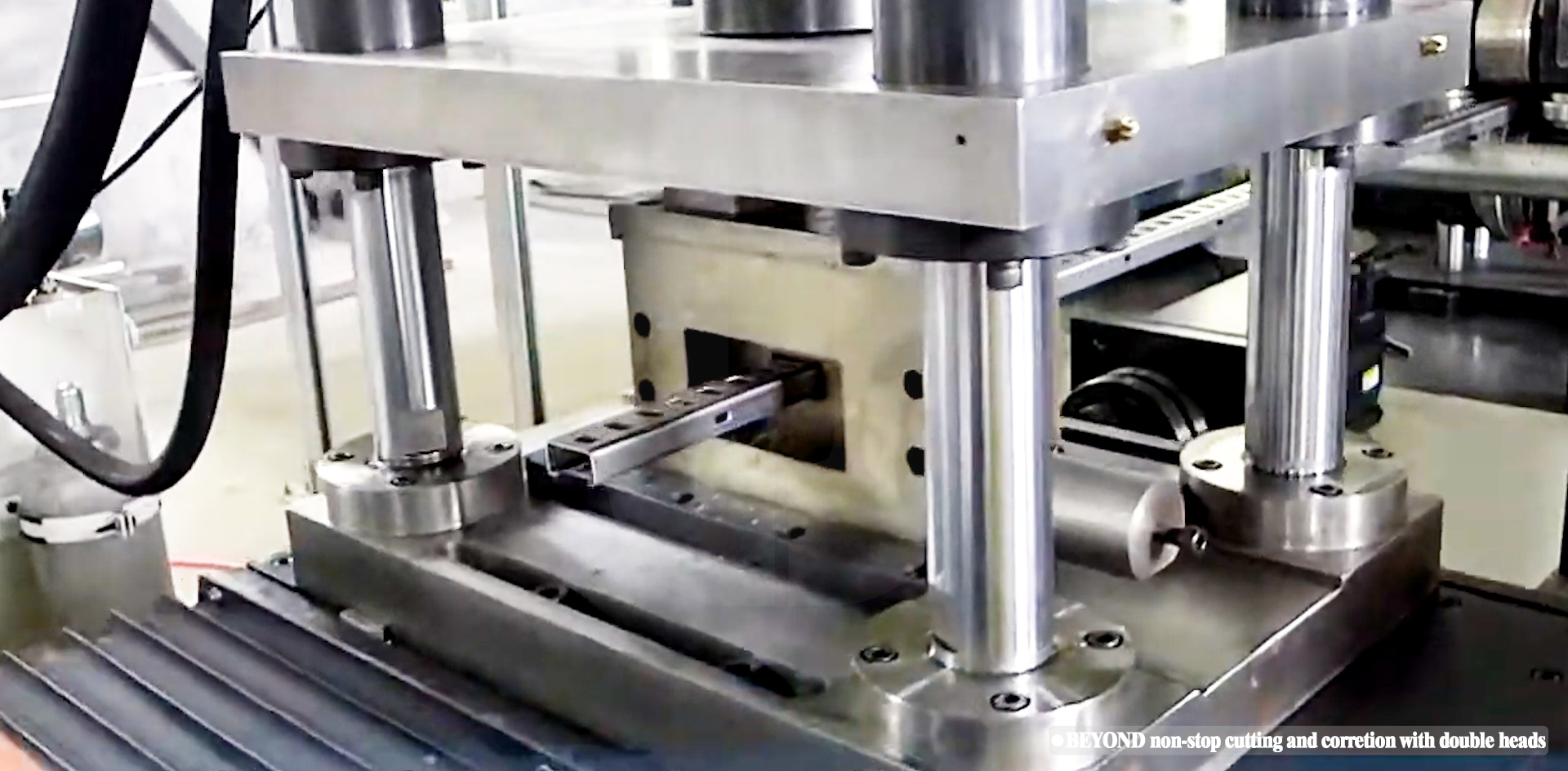

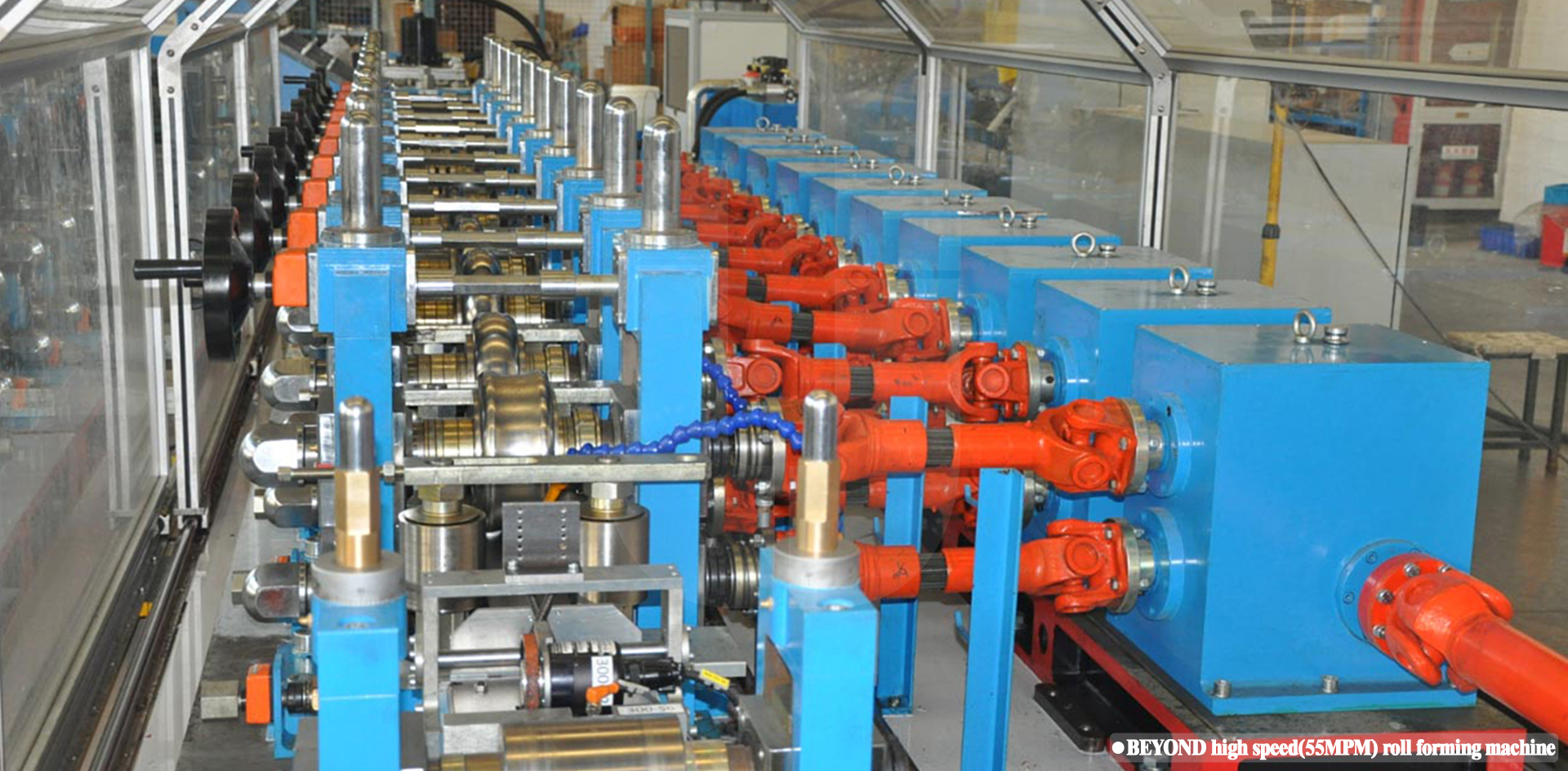

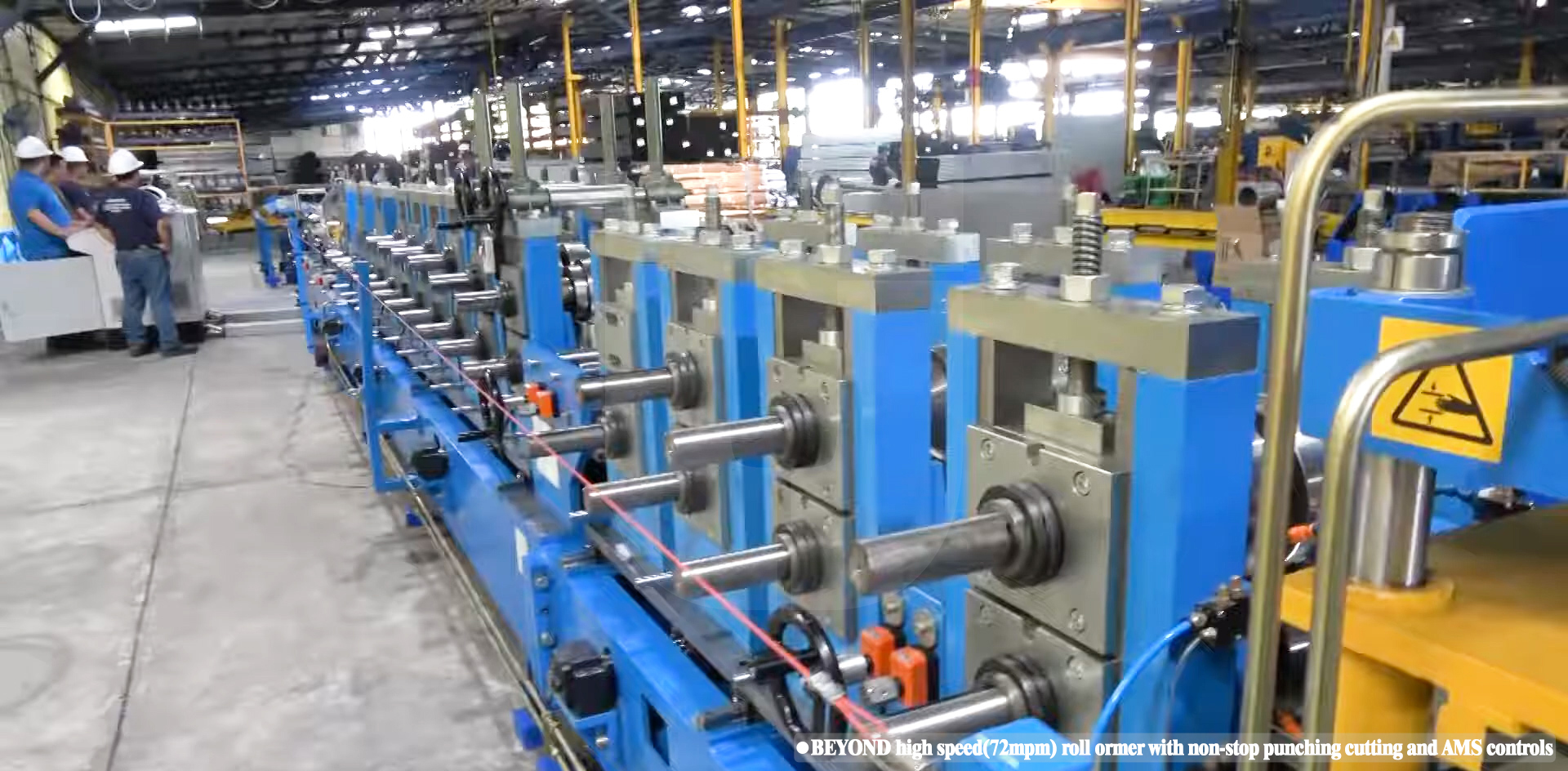

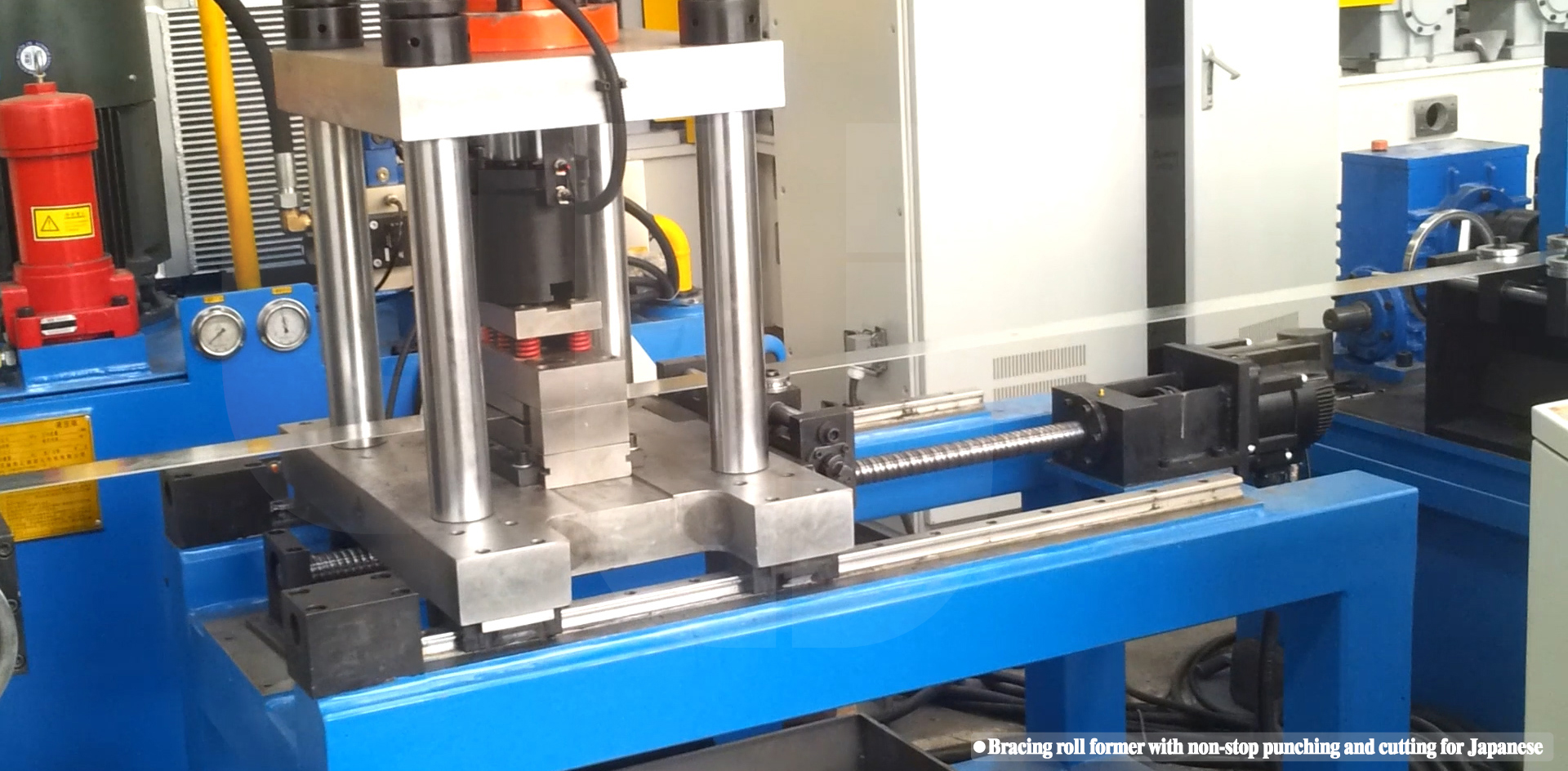

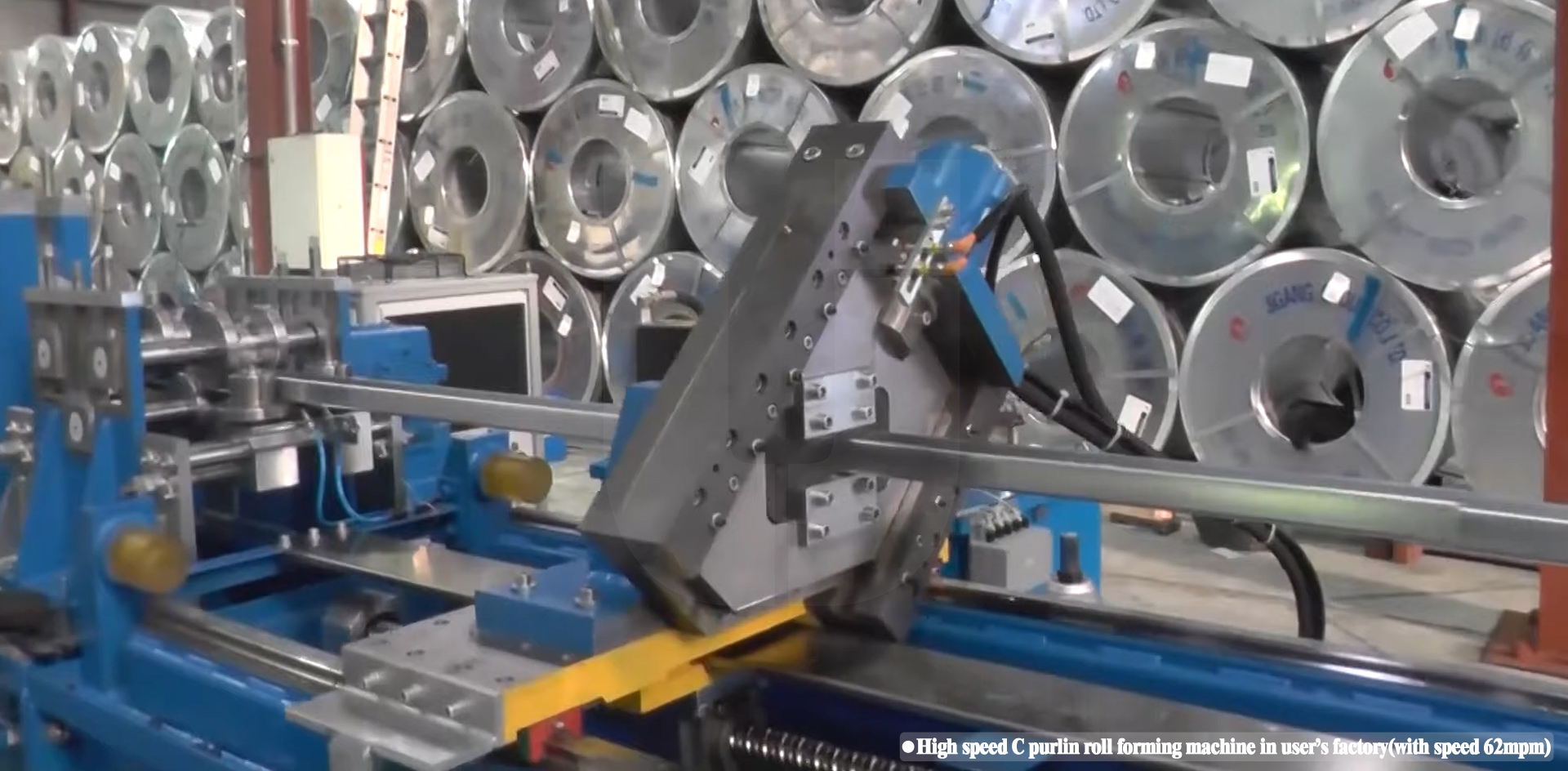

Mechanical Configuration

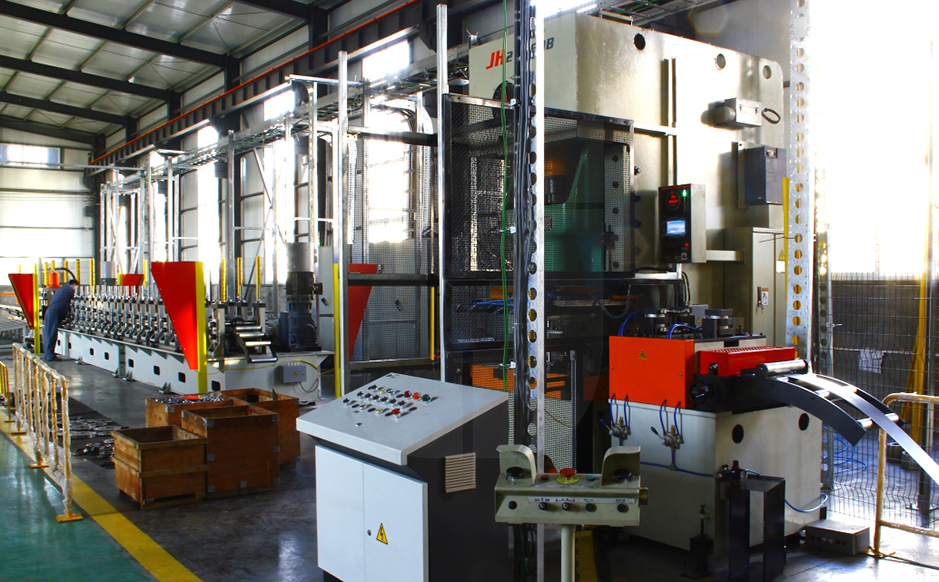

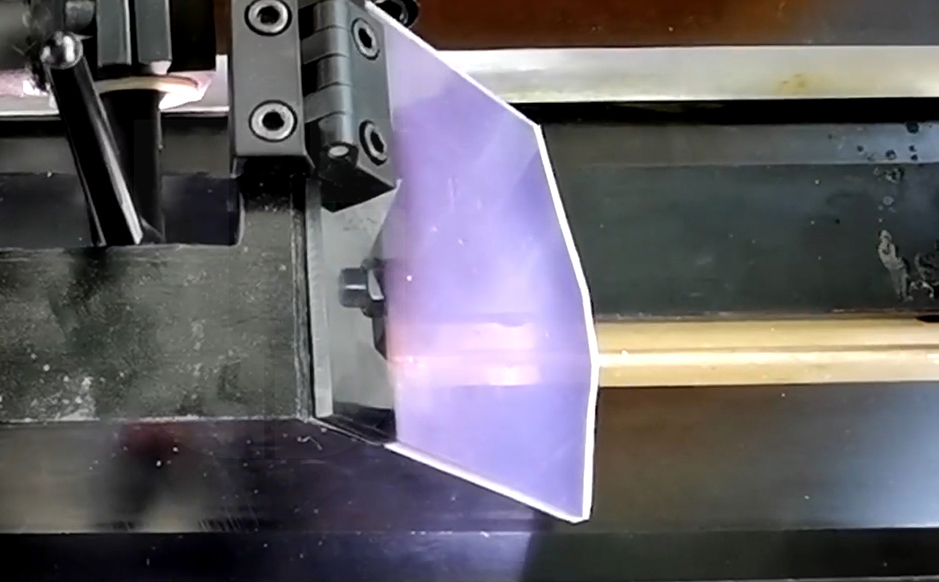

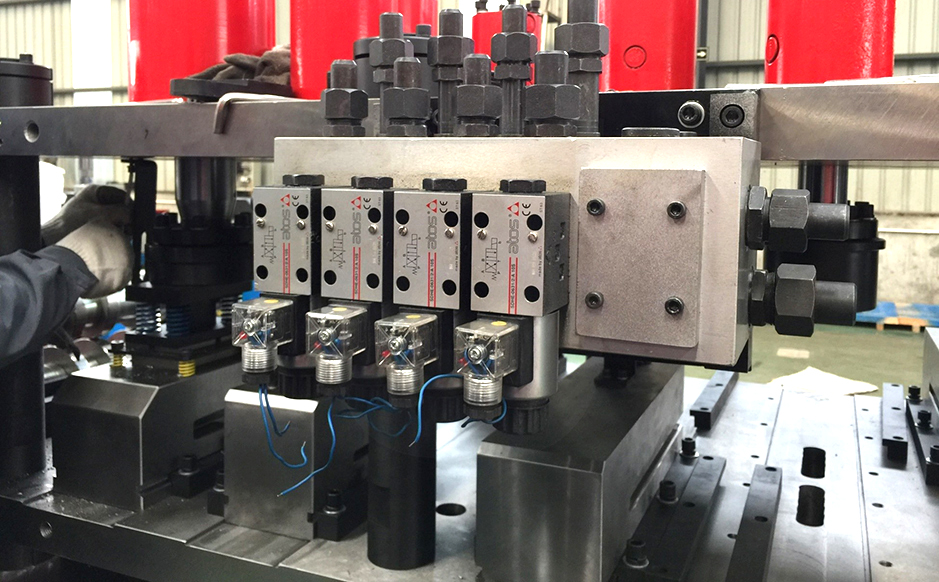

Unique Function

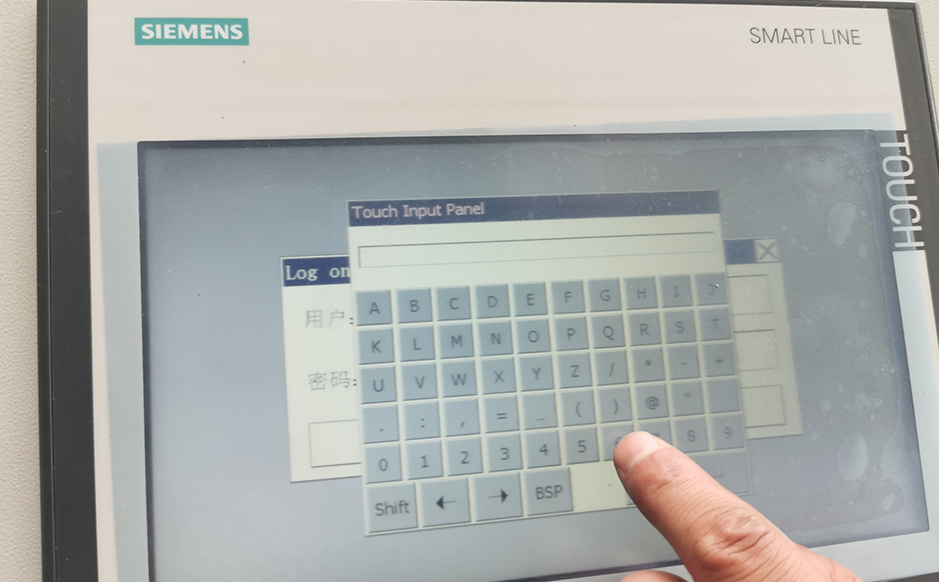

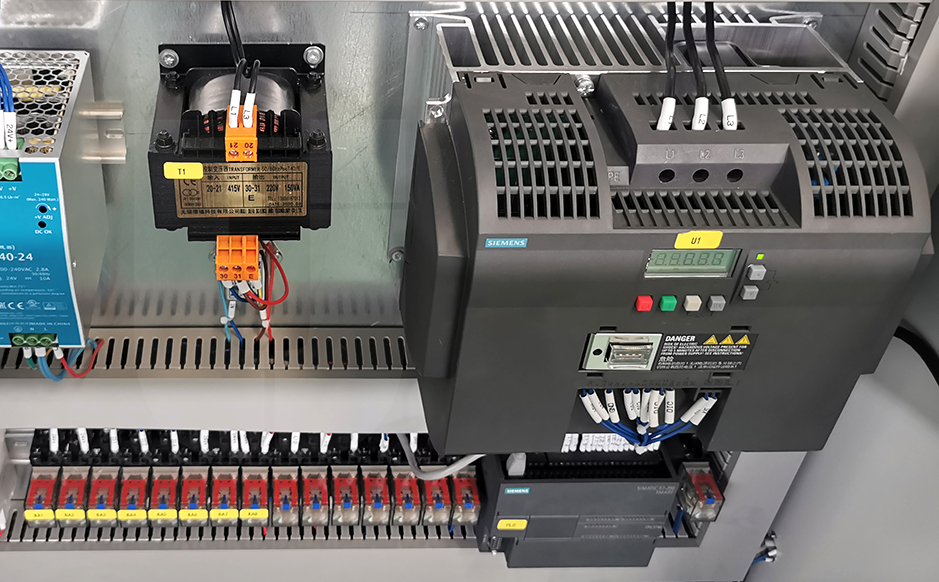

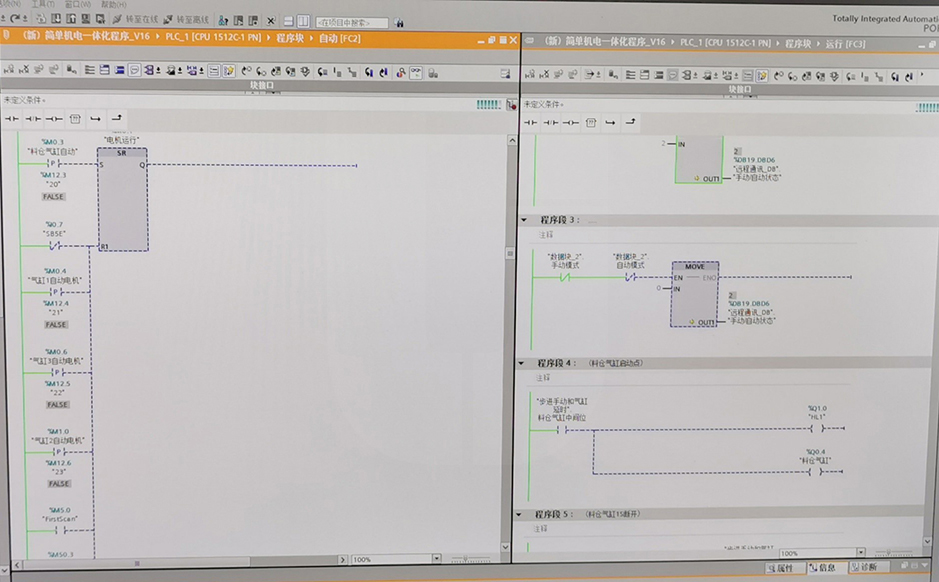

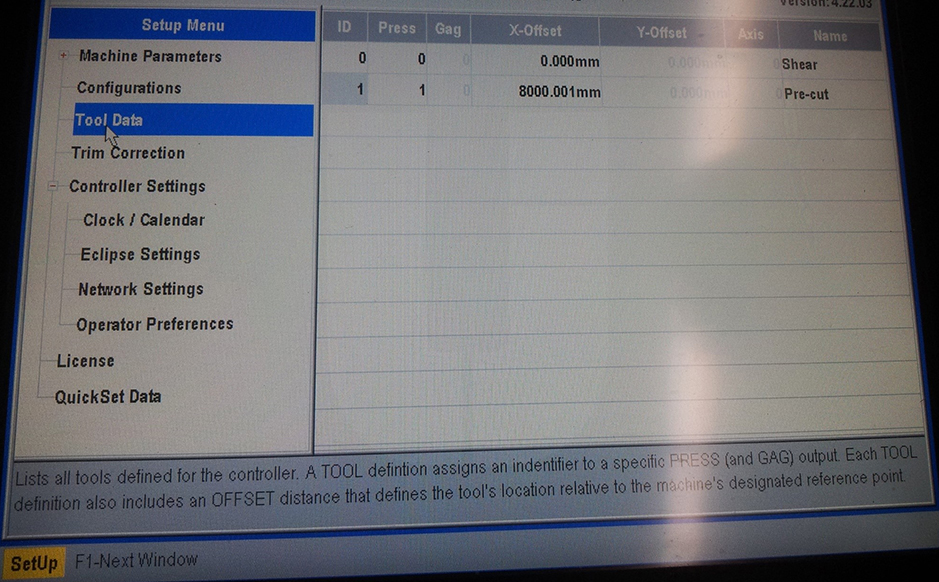

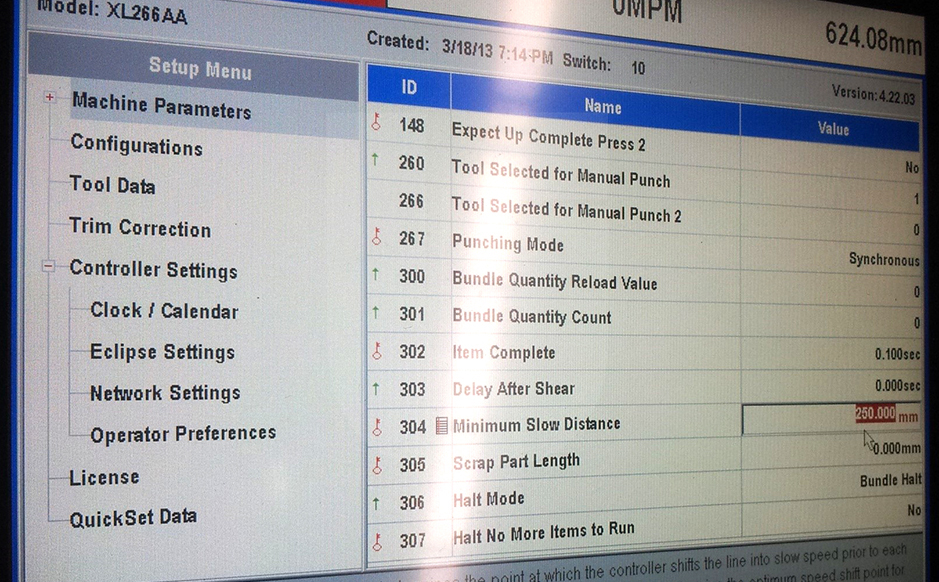

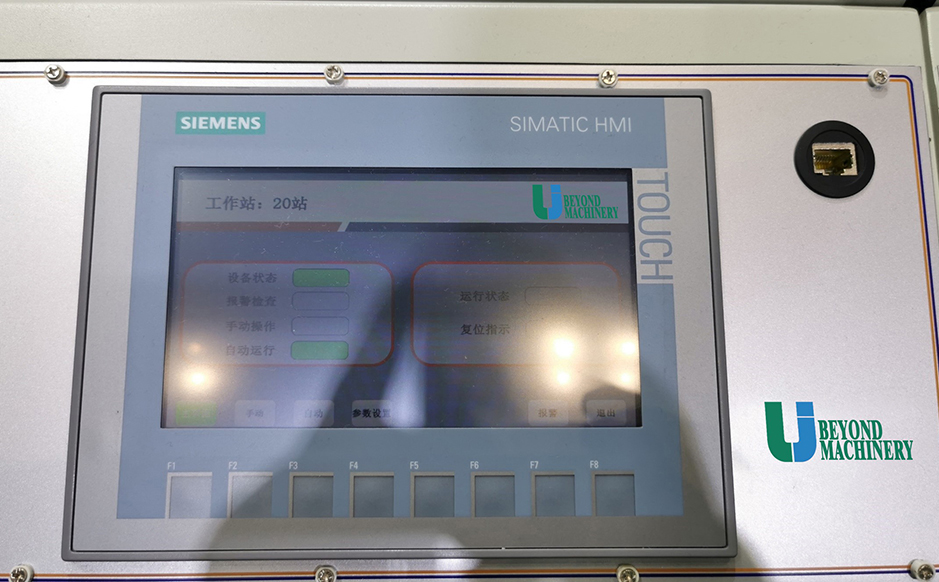

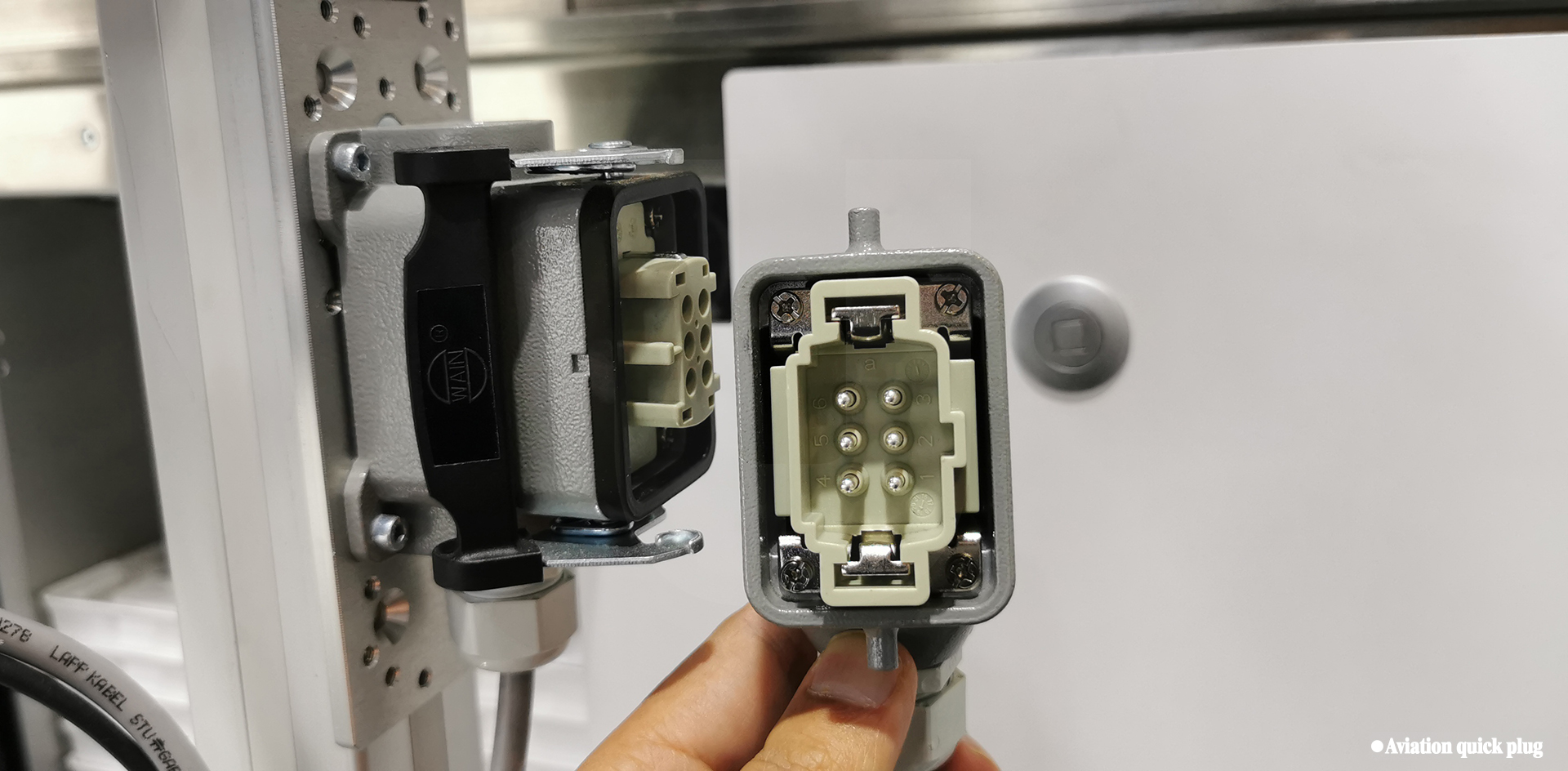

Electronic Control And Software

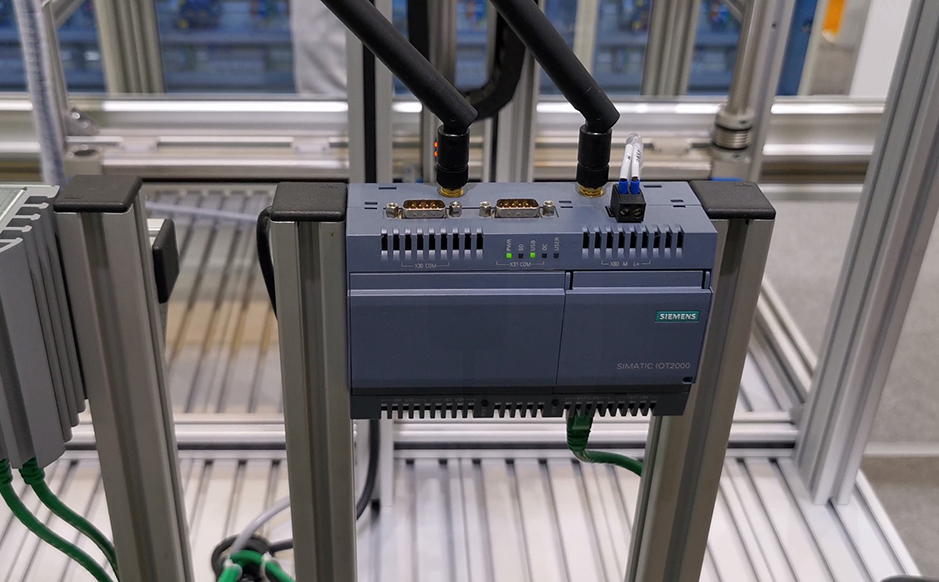

Remote Control And Diagnosis

| ITEM | PARAMETERS |

|---|---|

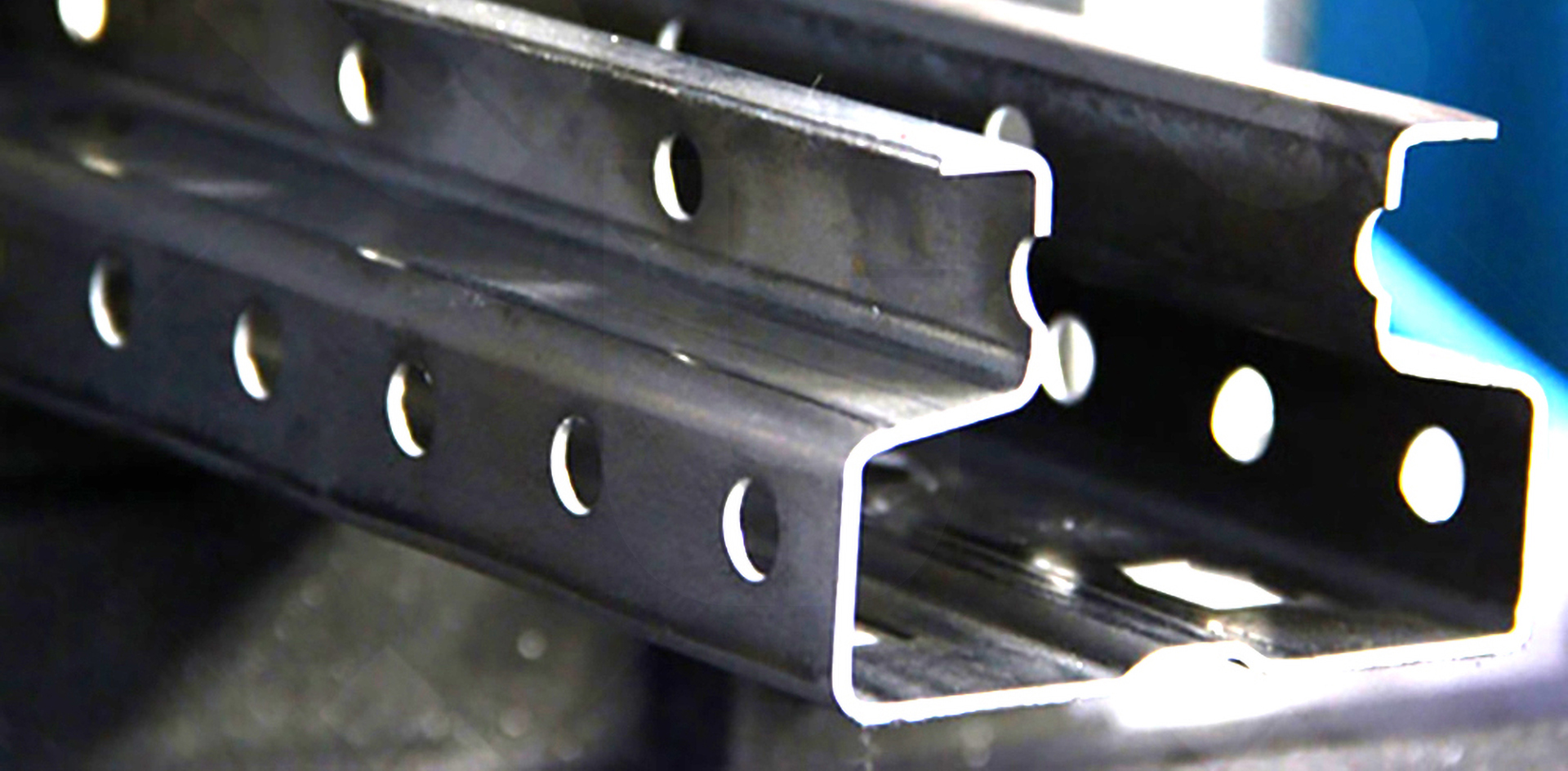

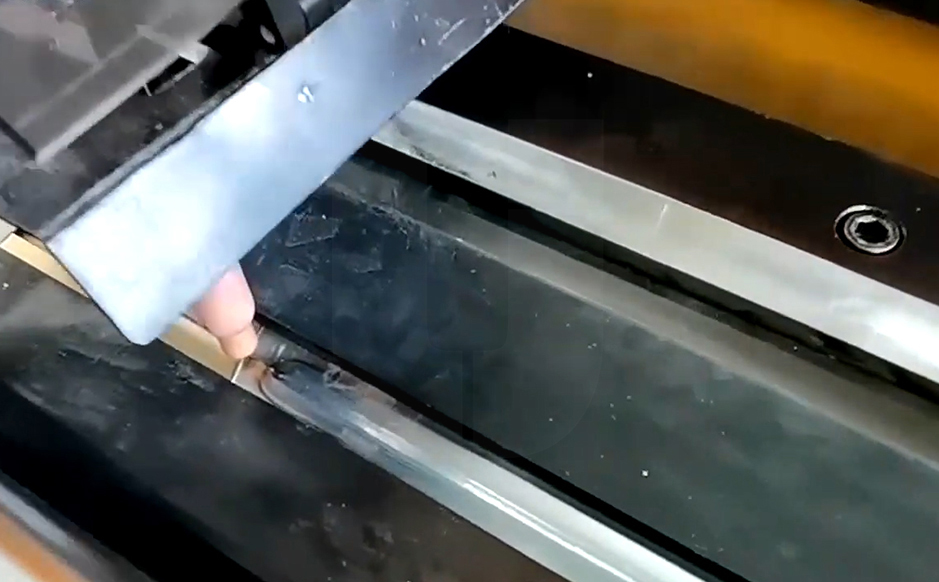

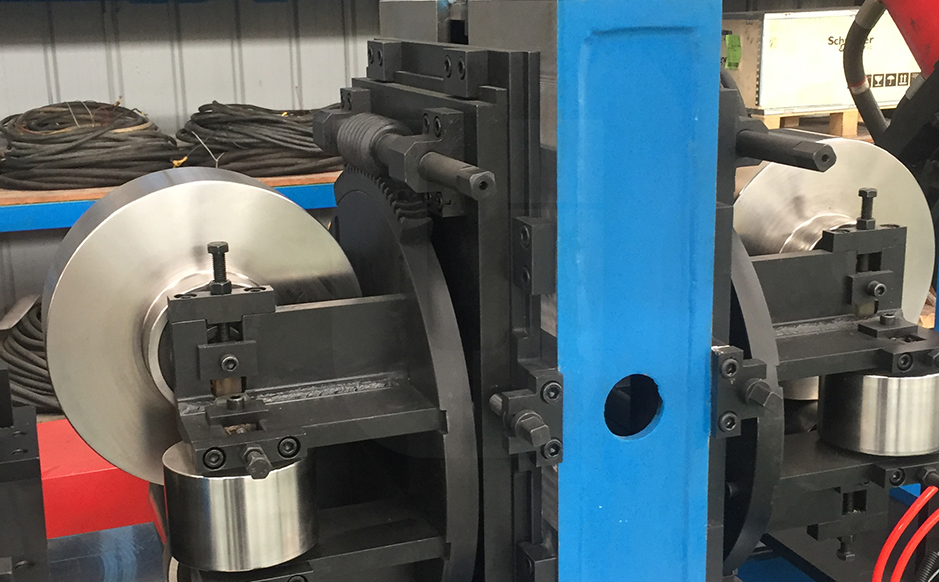

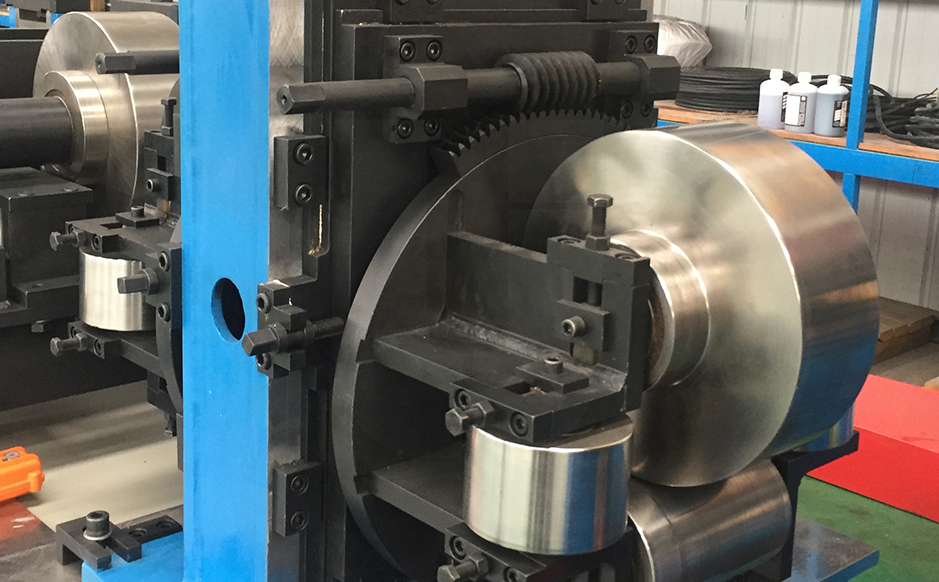

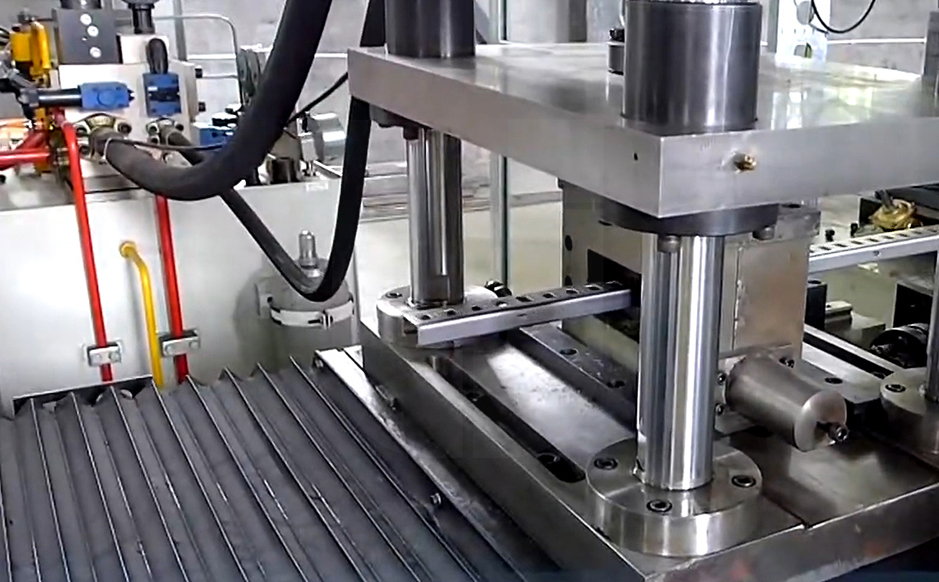

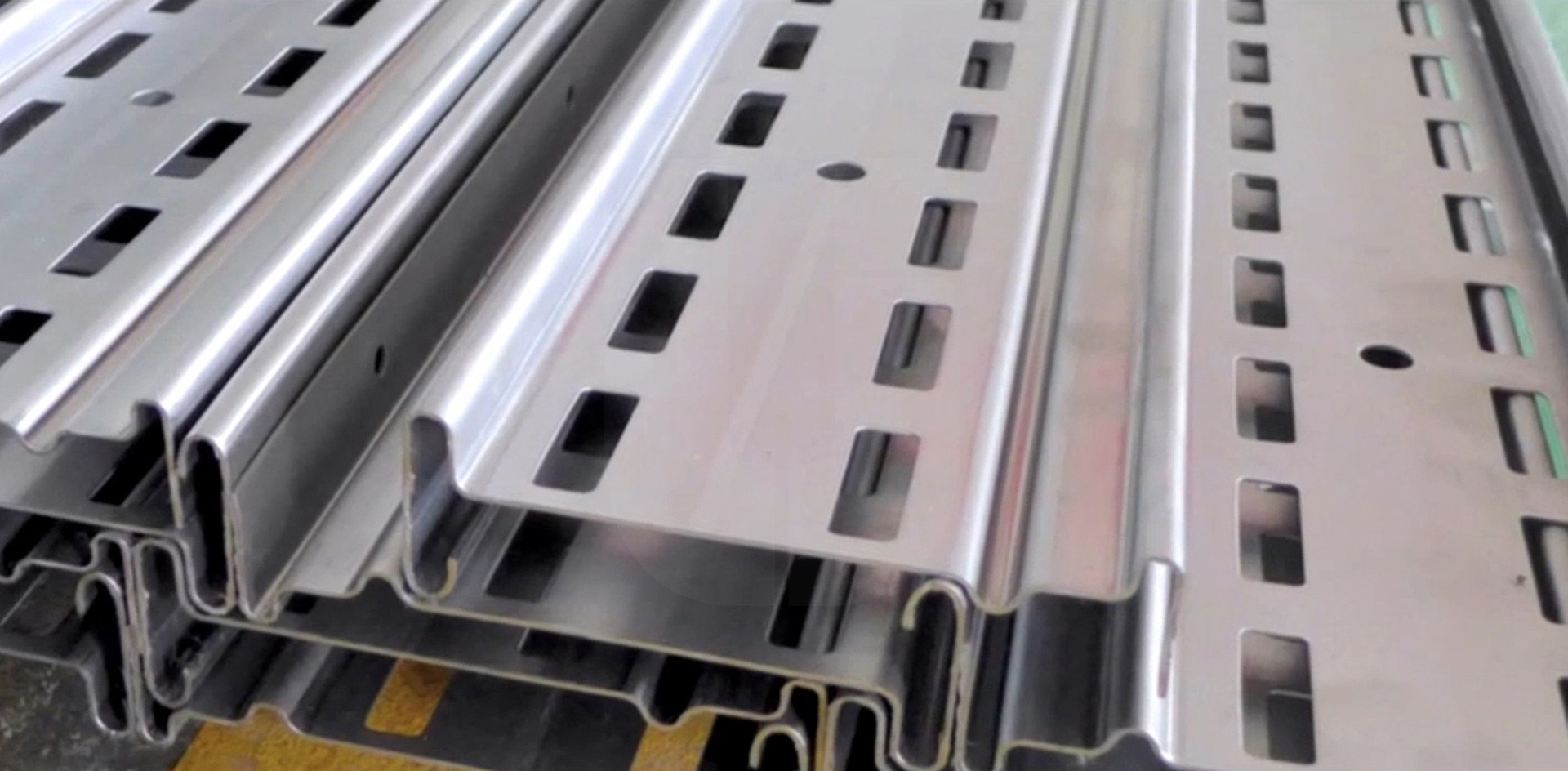

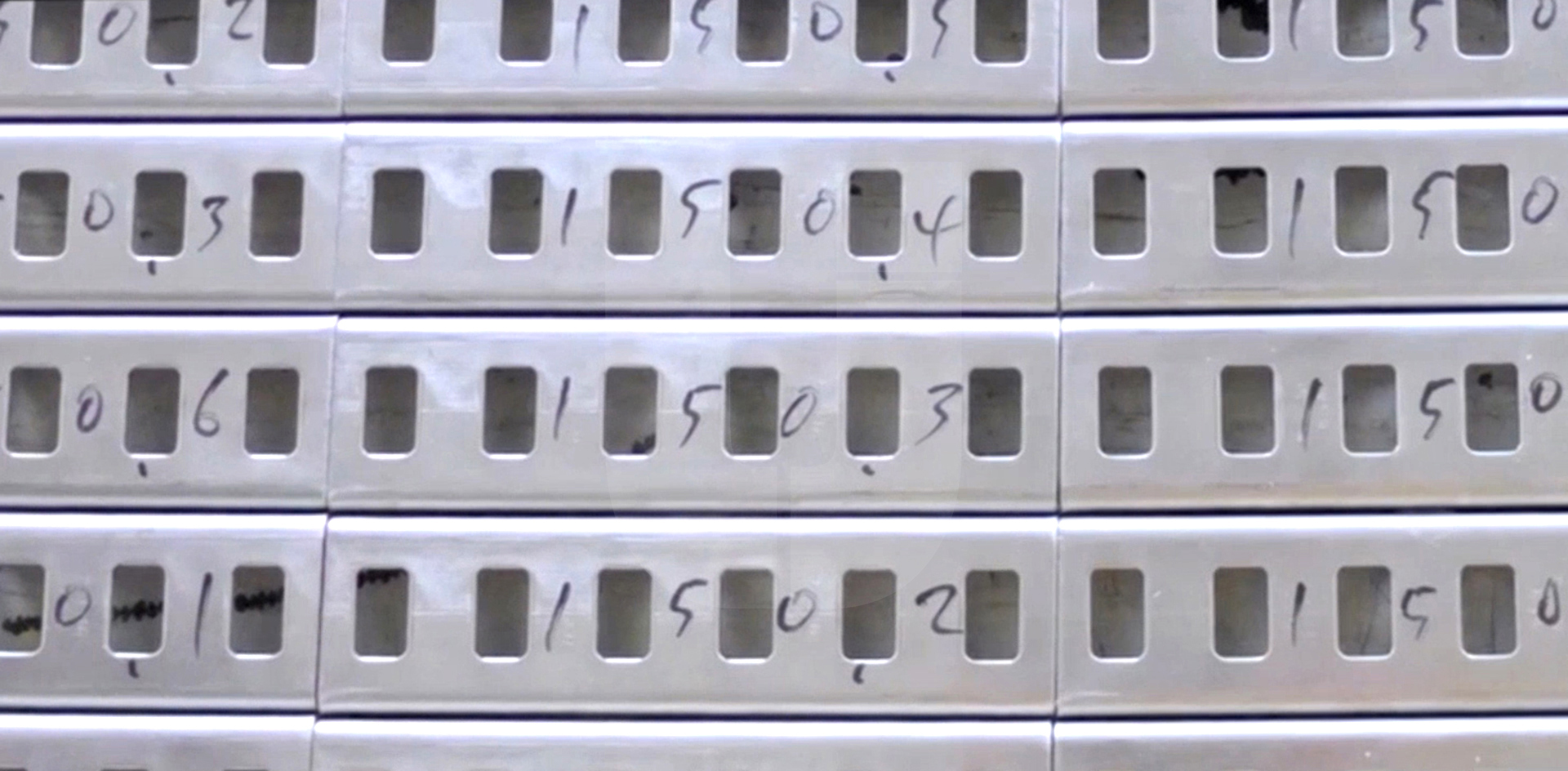

| Straightness(in the length direction of the product) | 1mm/3m(first one and only one can reach this straightness in China) |

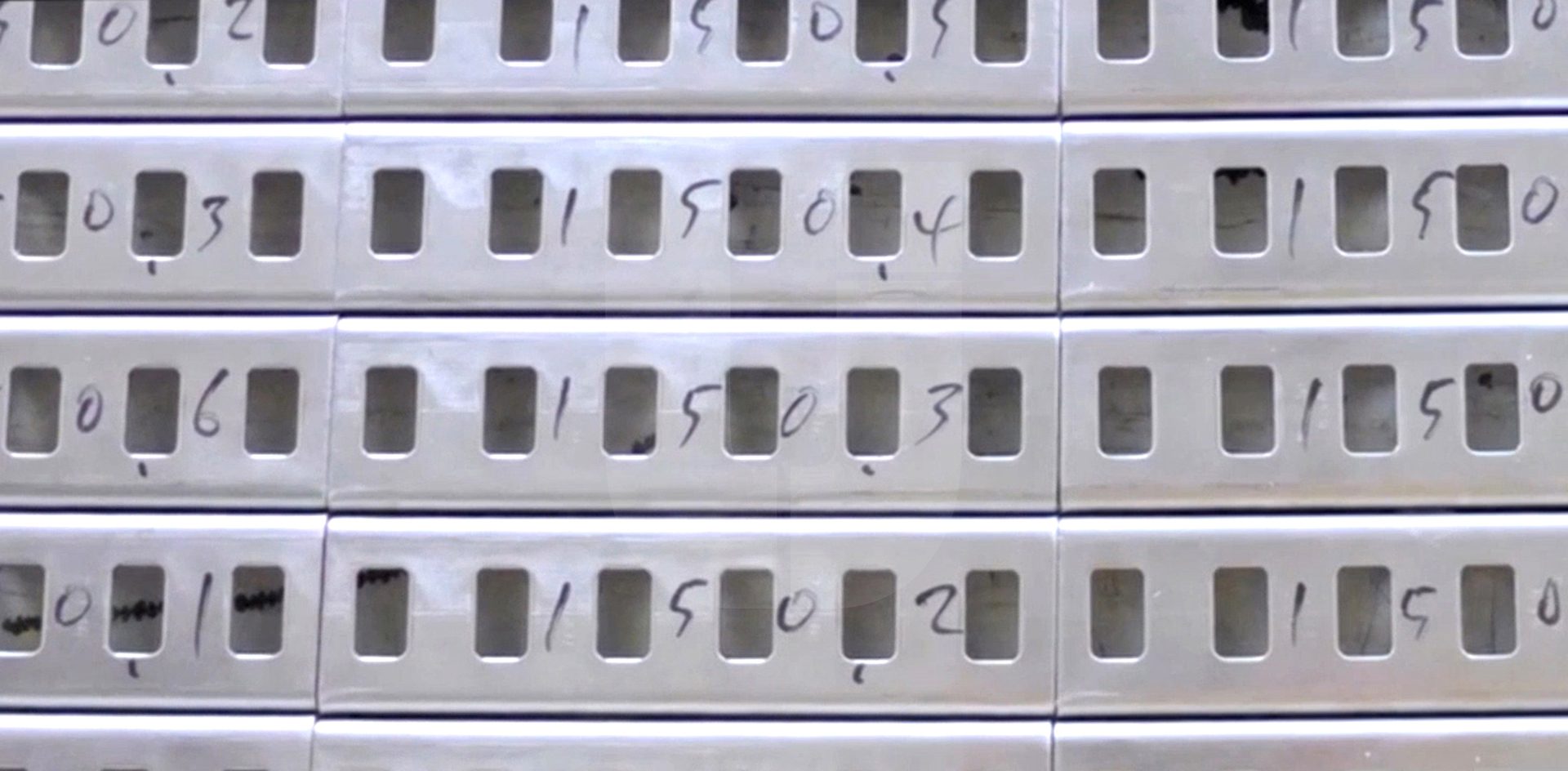

| Tolerance(in the width direction of the product) | -0.1mm~+0.2mm(first one and only one can reach this tolerance in China) |

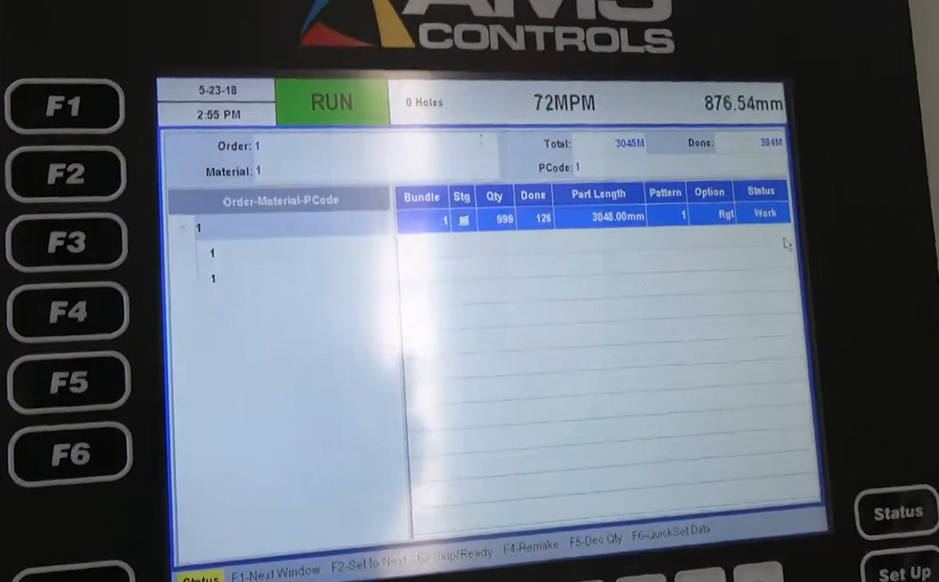

| Running Speed | 72m/min(first one and only one able to reach this speed in China) |

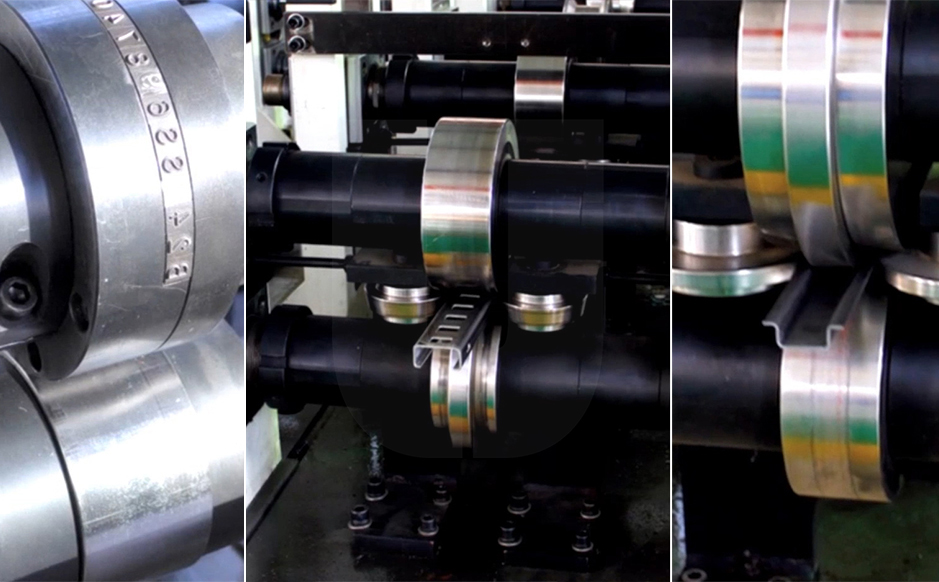

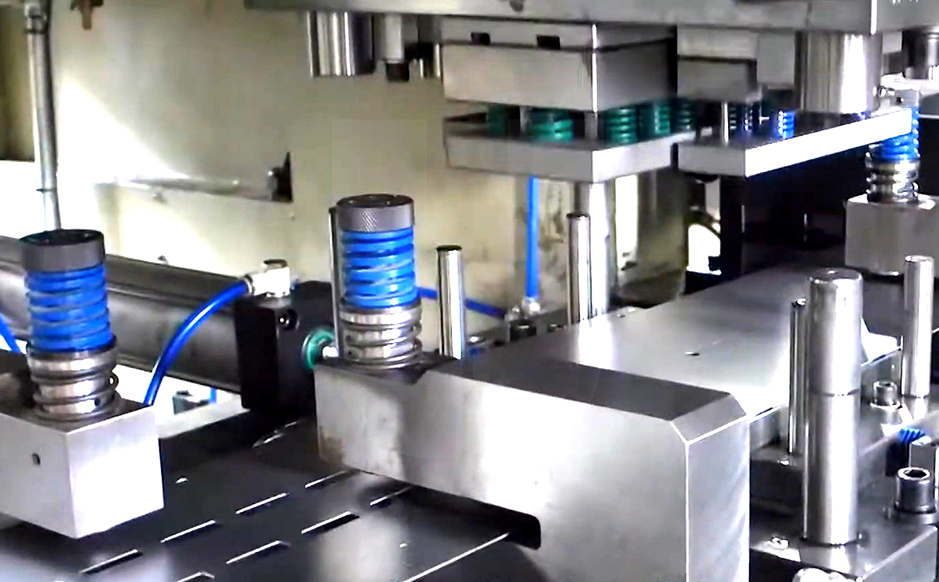

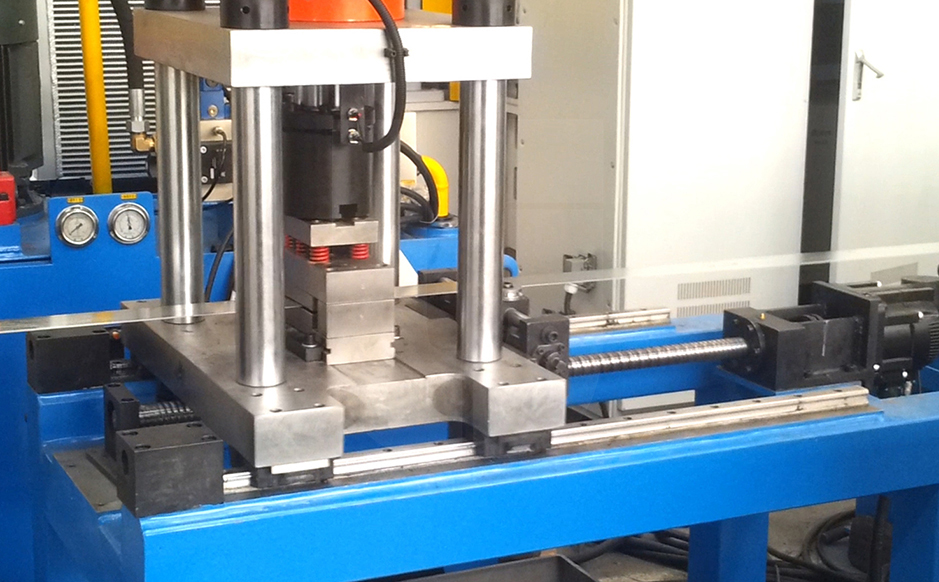

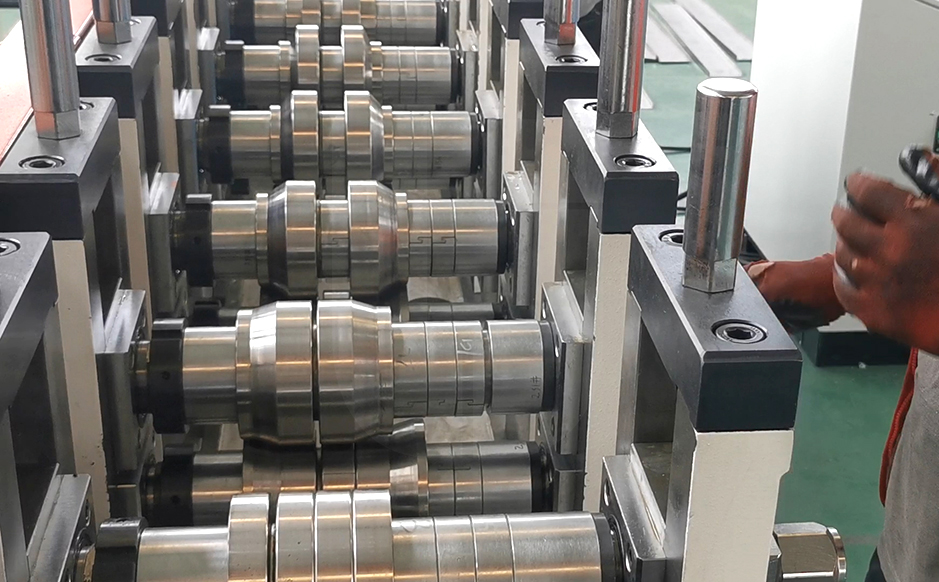

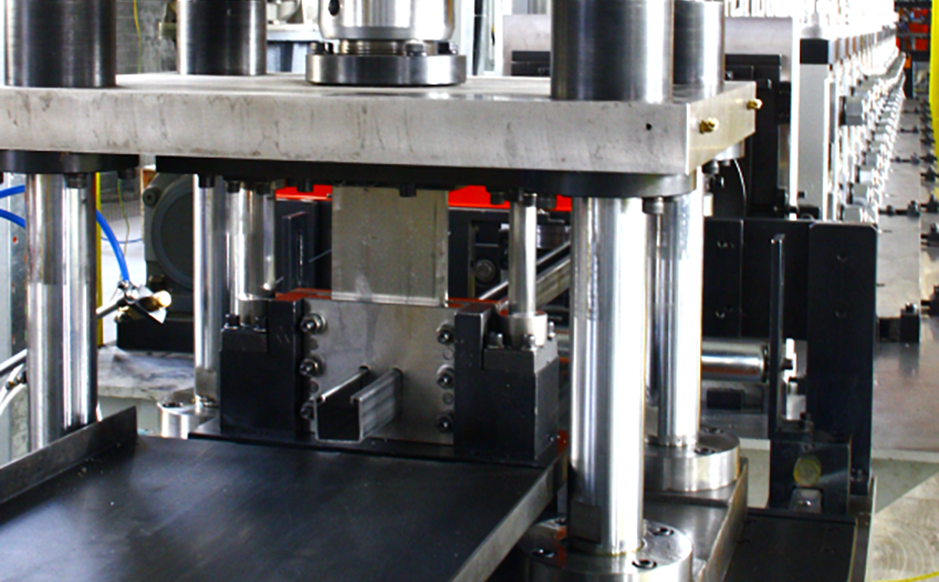

| Materials For Forming Rollers+Punching Dies | D2(DIE Steel with High Wear Resistance hardness ≥59HRC)+DC53(hardness:62-63HRC with service life of 5 million times) |

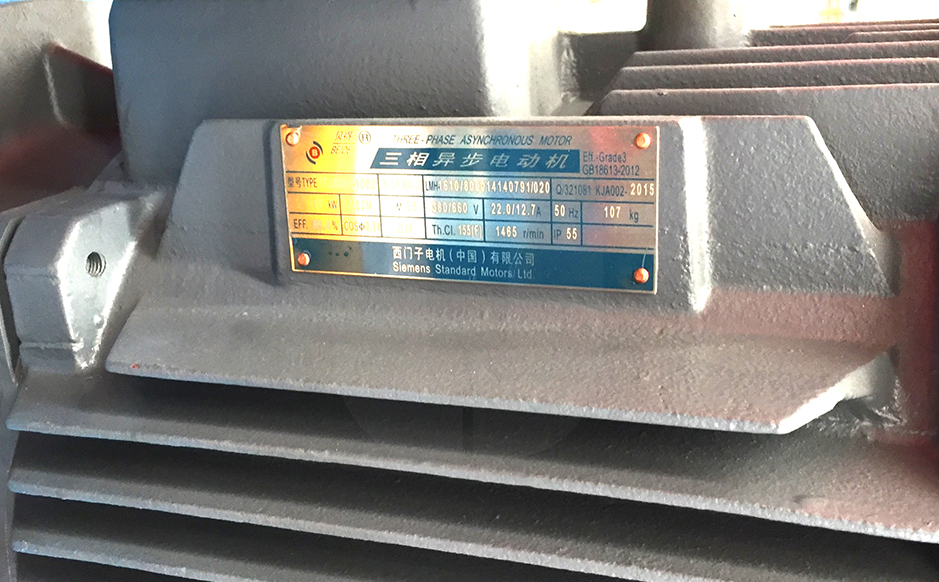

| Motor and Reducer | SIEMENS,Germany | SEW,Germany |

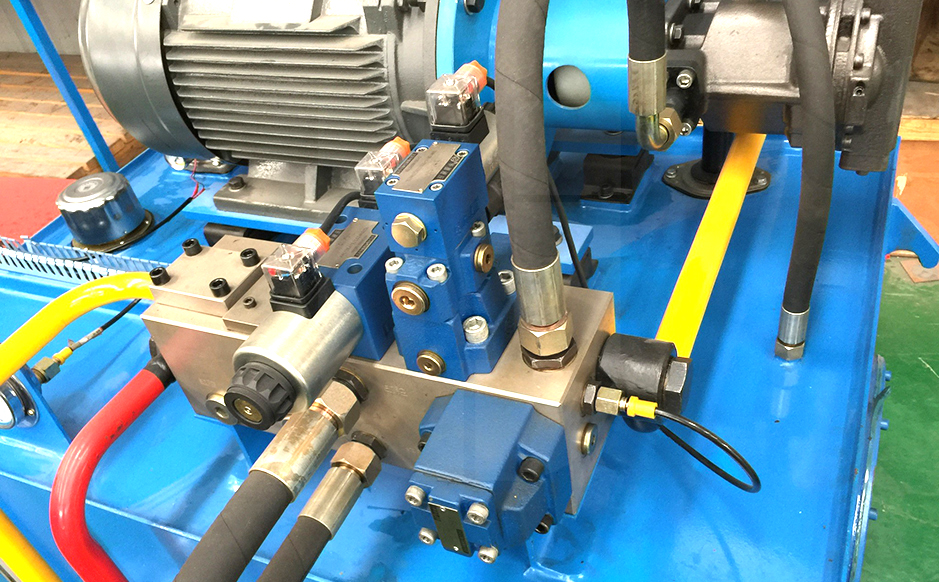

| Hydraulic Valve | Rexroth Bosch, Germany |ATOS,Italy |

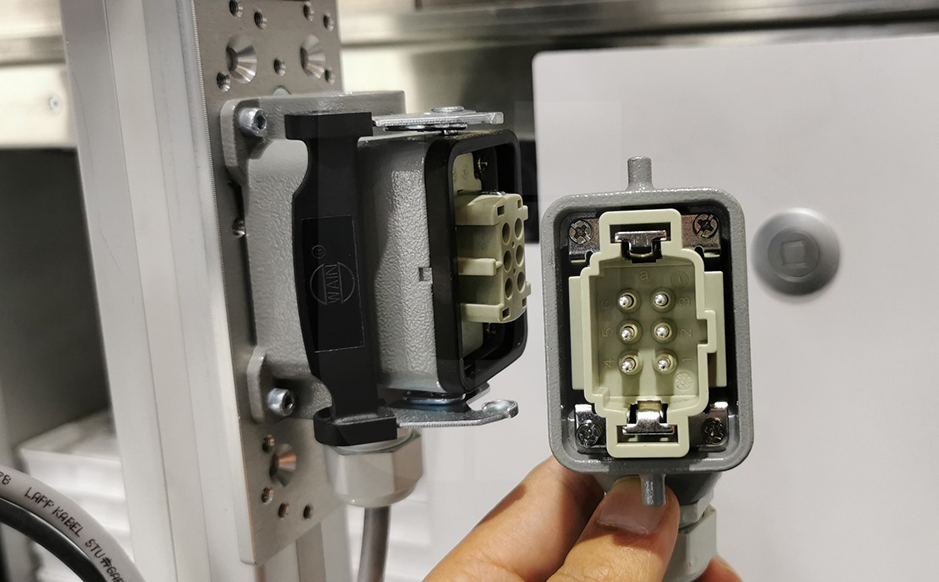

| Electronic Control | PLC:SIEMENS Frequency converter:SIEMENS Touch screen(14inch):SIEMENS |

| High Automation | Auto-stacking and packing available(to reduce at least 4 workers per shift) |

Brand Philosophy

“BEYOND Represents

Chinese Quality Standard”

Chinese Quality Standard”

BEYOND is not only a historical summary of the past

BEYOND is also the requirement and mission for the current stage

BEYOND is the foreshadowing and design for the future blueprint

BEYOND is also the requirement and mission for the current stage

BEYOND is the foreshadowing and design for the future blueprint

BEYOND is not only a symbol

But also represents the level of

China's manufacturing industry

But also represents the level of

China's manufacturing industry

Get Offer On

Get Offer On

Scan To Add With Whatsappor

Manually Add 008618018640828